crwdns2915892:0crwdne2915892:0

If your iPhone XR screen is cracked, not responding to touch, or not showing a picture when your phone is powered on, use this guide to restore your iPhone to working order with a new screen, a.k.a. display assembly.

This guide is meant to be used with complete replacement screens only. The replacement screen should come pre-mounted on a frame and have a thin metal LCD shield pre-installed on the back. If that LCD shield is missing, follow this more in-depth guide to replace the screen while keeping your old LCD shield.

The combined earpiece speaker + sensor assembly affixed to the back of the display is paired to your individual iPhone from the factory, so you must transfer it from your old display to your new one during any display replacement. It contains the flood illuminator, which is part of the biometric Face ID security feature. If it is damaged or replaced, Face ID will cease to function, so take extra care not to damage any of these components during this procedure. If damaged, only Apple can restore Face ID function.

Note: True Tone functionality is disabled after a screen replacement, even when using an original Apple screen.

crwdns2942213:0crwdne2942213:0

-

-

Power off your iPhone before beginning disassembly.

-

Remove the two 6.7 mm-long pentalobe screws at the bottom edge of the iPhone.

-

-

-

Measure 3 mm from the tip and mark the opening pick with a permanent marker.

-

-

-

Lay overlapping strips of clear packing tape over the iPhone's screen until the whole face is covered.

-

If you can't get the suction cup to stick in the next few steps, fold a strong piece of tape (such as duct tape) into a handle and lift the screen with that instead.

-

-

crwdns2935267:0crwdne2935267:0Clampy - Anti-Clamp$24.95

-

Pull the blue handle backwards to unlock the Anti-Clamp's arms.

-

Slide the arms over either the left or right edge of your iPhone.

-

Position the suction cups near the bottom edge of the iPhone—one on the front, and one on the back.

-

Squeeze the cups together to apply suction to the desired area.

-

-

-

Pull the blue handle forward to lock the arms.

-

Turn the handle clockwise 360 degrees or until the cups start to stretch.

-

Make sure the suction cups remain aligned with each other. If they begin to slip out of alignment, loosen the suction cups slightly and realign the arms.

-

-

-

Heat an iOpener and thread it through the arms of the Anti-Clamp.

-

Fold the iOpener so it lays on the bottom edge of the iPhone.

-

Wait one minute to give the adhesive a chance to release and present an opening gap.

-

Insert an opening pick under the screen and the plastic bezel, not the screen itself.

-

Skip the next three steps.

-

-

-

Use a hairdryer or heat gun, or prepare an iOpener and apply it to the lower edge of the iPhone for about a minute in order to soften up the adhesive underneath.

-

-

-

If you're using a single suction handle, apply it to the bottom edge of the phone, while avoiding the curved portion of the glass.

-

-

-

Pull up on the suction cup with firm, constant pressure to create a slight gap between the front panel and rear case.

-

Insert an opening pick under the screen and the plastic bezel, not the screen itself.

-

-

-

Slide the opening pick around the lower left corner and up the left edge of the iPhone, slicing through the adhesive holding the display in place.

-

-

-

-

Re-insert your pick at the bottom edge of the iPhone, and slide it up the right side to continue separating the adhesive.

-

-

-

Slide the opening pick around the top corner of the display, while gently pulling or wiggling the display down in the direction of the Lightning port.

-

Slide the pick to the opposite corner and cut any remaining adhesive securing the display.

-

-

-

Pull on the small nub on the suction cup to remove it from the front panel.

-

-

-

Open the iPhone by swinging the display up from the left side, like the back cover of a book.

-

Lean the display against something to keep it propped up while you're working on the phone.

-

-

crwdns2935267:0crwdne2935267:0Magnetic Project Mat$19.95

-

Remove three 1.2 mm Y000 screws securing the battery connector cover bracket.

-

Remove the bracket.

-

-

-

Use the point of a spudger to pry the battery connector straight up out of its socket.

-

Bend the connector slightly away from the logic board to prevent it from accidentally making contact with the socket and providing power to the phone during your repair.

-

-

-

Remove the two 1.2 mm Y000 screws securing the display connector bracket.

-

Remove the bracket.

-

-

-

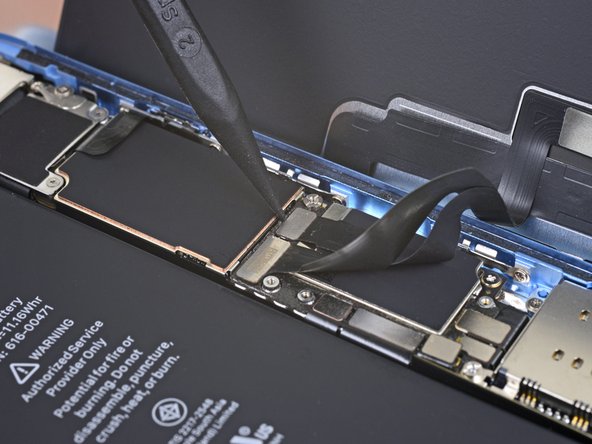

Use the tip of a spudger to pry up and disconnect the digitizer cable.

-

-

-

Use the tip of a spudger to disconnect the display cable connector.

-

-

-

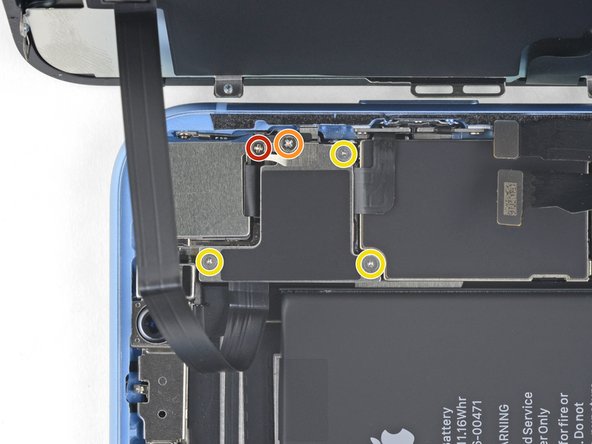

Remove the five screws securing the logic board connector bracket to the rear case:

-

One 1.3 mm Phillips #000 screw

-

One 1.5 mm Phillips #000 screw

-

Three 1.2 mm Y000 screws

-

Remove the bracket.

-

-

-

Use the tip of a spudger to pry the front sensor assembly connector up from its socket.

-

-

-

Remove the display assembly.

-

-

-

Remove the four screws securing the speaker/sensor assembly to the back of the display:

-

Two 1.6 mm Phillips screws

-

One 2.3 mm Phillips screw

-

One 1.2 mm Y000 screw

-

-

crwdns2935267:0crwdne2935267:0Tweezers$4.99

-

Using tweezers, gently flip the speaker assembly over—down and away from the top edge of the display.

-

-

-

Use a hairdryer, a heat gun, or a heated iOpener applied to the top front of the display for about a minute, in order to soften the adhesive securing the sensors.

-

-

-

Carefully slide the flat edge of a spudger underneath the flex cable below the microphone.

-

Twist gently to separate the microphone, while being careful not to strain or damage the flex cable.

-

If needed, use the point of the spudger to finish separating the microphone from its notch in the front panel. If the microphone remains difficult to separate, apply more heat.

-

-

-

Working left to right, slide an opening pick beneath the flex cable and underneath the proximity sensor + flood illuminator module.

-

Gently wiggle and lift to separate the module from its notch in the front panel.

-

-

-

Use tweezers to slide the small bracket straight up and off of the ambient light sensor.

-

-

-

Use tweezers to wiggle the ambient light sensor and lift it from its notch in the display.

-

-

-

If you successfully removed the entire ambient light sensor, as shown in the first photo, continue to the next step below.

-

If the white diffuser strip is detached and remains embedded in the display, as shown in the second photo, you will need to carefully lever it out along the top edge using a thin blade or pry tool. Re-applying heat first may make this task a bit easier.

-

-

-

Remove the earpiece speaker and front sensor assembly.

-

Proximity sensor

-

Flood illuminator

-

The module must be positioned so that these components are not obstructed by any adhesive.

-

Compare your new replacement part to the original part—you may need to transfer remaining components or remove adhesive backings from the new part before installing.

To reassemble your device, follow the above steps in reverse order.

Take your e-waste to an R2 or e-Stewards certified recycler.

Repair didn’t go as planned? Check out our Answers community for troubleshooting help.

crwdns2935221:0crwdne2935221:0

crwdns2935229:0361crwdne2935229:0

crwdns2947412:048crwdne2947412:0

Man, you guys have the best jobs. You get to take apart electronics and make outstanding repair guides for a living!

Where I can buy the screen?

Hi, you can buy the screen here in our store! Good luck with your repair!

What about the half dozen other steps of removing the back plate, transferring components and reassembling the device?

We put those steps into a separate guide, since not everyone needs them! If you need the more in-depth version, look here.