crwdns2915892:0crwdne2915892:0

Follow this guide to replace the fan on a Microsoft Surface Pro 4.

There is a significant chance that you may break the unreinforced and fragile display panel during this procedure. Be sure to apply adequate heat and be extremely careful while slicing through the adhesive. Wear safety glasses in case the glass shatters.

Applying new thermal paste during reassembly may improve the performance of your Surface. If you wish to do that, make sure you have new thermal paste and either high-concentration isopropyl alcohol or a specialized thermal paste cleaner.

crwdns2942213:0crwdne2942213:0

-

-

If your screen glass is cracked, keep further breakage contained and prevent bodily harm during your repair by taping the glass.

-

Lay overlapping strips of clear packing tape over the Surface’s screen until the whole face is covered.

-

Do your best to follow the rest of the guide as described. However, once the glass is broken, it will likely continue to crack as you work, and you may need to use a metal prying tool to scoop the glass out.

-

-

-

Heat an iOpener and apply it to the right edge of the Surface's screen for two minutes.

I have done dozens of Surface Pro tablet repairs; if your screen is cracked or chipped AT ALL, you WILL make it worse. Plan on replacing it. Even if it's not cracked or chipped, the likely hood of removing this screen without damage (LCD separation or heat marks in the corners) is very low. Ive tried everything from hot plates to heat mats and the iOpener and nothing is reliable enough. I found that using my Warner heat gun set at 800*c and working on half an edge at a time with a LOT of 91% alcohol in a drip bottle along the edge, along with a very thin guitar pick (not the ones sold here, they are too thick) is the trick to loosening the glue. Work on the side and bottom first. The top is going to be the hardest as the adhesive will stick to the wifi/bluetooth antenna and you WILL tear them (Ive had to replace a fair amount of them). There's a delicate trick to doing it, but it's too hard to describe. If you've never done this repair before, I do not recommend it; find a professional.

Hi, thanks for the information, Very valuable.

I'm about to do this because my battery and fan aren't working.

There's no way anybody can fix it properly near me. Got any other tip to try not to break the screen and or any flex?

I've done works like this on small tablets and phones, but never this pc. I'll try to go slow.

Thanks again for your experience information.

-

-

-

Take note of the screen adhesive layout before continuing:

-

These areas only contain adhesive and are safe to cut.

-

The display board and flex cables sit here close to the edge. Cut carefully and don't insert the pick more than 1/8 inch (3 mm).

-

Fragile antenna cables lie under this part of the screen. Carefully follow the procedure in step 13 to avoid damaging them. The adhesive is also the thickest here.

The bottom red section is narrow and not as thick as the bevel indicates. I went too deep with my tool and cut through a ribbon thinking that I could send my tool as deep as the black bevel edge. its like half that.

I did a screenshot of this image to always see it while progressing through the steps and did exactly the same mistake. I read every comment in the steps below but yours only now :( On my device it's 5mm from the edge of the screen glass to the ribbon.

I cut through as well, but was able to carefully solder the edges together enough to make a connection - works fine.

The sensitive areas are on the opposite side from the easy areas - YET - there is nothing in the diagram to indicate which is the keyboard attaching edge or any other identifier.

-

-

-

Insert an opening pick into the top-right speaker cutout on the screen and slide the pick between the glass and speaker grille.

-

-

-

Rotate the pick toward the bottom of the Surface to slide it underneath the lower edge of the speaker cutout.

-

-

-

Slide the pick down the right edge of the Surface to slice through the adhesive under the screen.

-

Leave this opening pick in the right edge to prevent the adhesive from resealing.

-

-

-

Reheat your iOpener and apply it to the bottom edge of the Surface's screen for two minutes.

-

-

-

Insert a new opening pick into the bottom-right corner and slide it around the corner toward the bottom edge.

-

Slide the pick along the bottom edge of the Surface to cut through the screen adhesive.

-

Leave this pick in the bottom edge to prevent the adhesive from resealing.

Yep. I scratched the corner of the LCD with the pick. Take the warning seriously folks! It’s really easy to do.

The warning says to not insert it more than 12mm but it should be not more than 5mm. There is a ribbon/display connection at the bottom and i damaged it.

Exactly! The bezel is much smaller at the bottom side and you will hit the LCD if you push deeper than 6mm.

mowny -

-

-

-

Reheat your iOpener and apply it to the left edge of the Surface's screen for two minutes.

-

-

-

Insert a new opening pick into the bottom left corner and slide it around the corner toward the left edge.

-

Slide the pick along the left edge of the Surface to cut through the screen adhesive.

-

Leave this pick in the left edge to prevent the adhesive from resealing.

-

-

-

Reheat your iOpener and apply it to the top edge of the Surface's screen for two minutes.

-

-

-

Round the left corner with the opening pick and slide it along the top edge of the Surface. Stop when the pick is 2.75 inches (70 mm) away from the left edge.

The right antenna is kind of P shaped (rotated 90° to the right) with the small end facing the middle. I'd suggest to stop at the middle when loosening the left antenna and to do the same thing coming from the right.

-

-

-

Insert the point of a pick under the screen where you just stopped cutting. Don't insert the pick deeper than the edge of the bezel.

-

Carefully roll the pick to the right, pressing the long edge of the pick into the screen adhesive underneath the bezel, cutting the adhesive as you go. Don't slide the pick along the edge of the Surface.

-

Repeat this motion of inserting the point of the pick where you just cut, and rolling to the right all along the top edge of the Surface, until the pick is 2.5 inches (64 mm) from the right edge of the Surface.

Bij mijn exemplaar bleek het onmogelijk om de bovenrand volgens de aanwijzingen los te maken. Ik heb de boel vele keren opgewarmd en ben meerdere malen met het plectrum langs de rand gegaan. Maar er beleef iets hardnekking vastplakken. Ik moest uiteindelijk de lijmverbindingen los maken zoals bij de andere randen. Achteraf bleek dat bij het gedeelte waar de antennes zaten het frame en het scherm volledig met elkaar verlijmd zaten met de antennes er tussen. Dat kostte me uiteindelijk de antennes. Gelukkig geen schade aan andere zaken. Niet zo'n grote ramp want ik kon nog antennes bestellen. Maar hou er rekening mee.

Don't fret about the antennae. You can buy a replacement antennae bar on Ebay for £10-15. Given that many commenters report damaging at least one, if I were to do this again, I'd just buy a new bar (before starting) and get the screen off faster.

-

-

-

-

Once you cut the adhesive over the antennas (8.5 inches, or 22 cm, from the left edge), slide the pick the rest of the way along the top edge of the surface and round the top right corner to slice through any remaining adhesive.

-

-

-

Very slowly lift the screen assembly away from the Surface case. If you encounter any resistance, stop and check that all the adhesive is separated.

-

Use an opening pick to cut through any remaining adhesive.

iFixit should show the closeups of the edges of the chassis, after the screen has been removed showing where the glue needed to be cut and the proximity to other internal parts so the repair tech can anticipate what they can't see and avoid being too aggressive. Show the difference between a clean removal vs one that was problematic in breaking the seals around the edges.

-

-

-

Lift the top of the screen assembly away from the case while sliding the bottom of the screen closer to the motherboard display connectors.

-

Gently lay the screen down on the case with the connectors facing up. Take care to avoid creasing the display cables.

-

-

crwdns2935267:0crwdne2935267:0Tweezers$3.99

-

Use one tip of a pair of angled tweezers to pry up the EMI shield from the gaps between the "teeth."

-

Repeat this procedure at different points around the perimeter of the shield until it is free.

-

-

-

Use your tweezers to remove the two EMI shields covering the display cable connectors.

-

-

-

Pry up with the flat end of a spudger to disconnect each display cable from the motherboard.

-

-

-

Remove the screen from the Surface.

-

During reassembly, pause here and follow this guide to replace the screen adhesive.

-

-

-

Use a T5 Torx screwdriver to remove the four 4.5 mm screws securing the antenna support bracket.

This screw bit was not included in the battery replacement kit. Only Philips and Flathead were included.

This Torx bit was not included in the battery replacement kit. Only a Philips and Flathead bit

this screw bit was not included, lucky I did not get the battery from you guys and that battery had this kind of screw driver included.

used phillips bit and stripped screws

-

-

-

Carefully remove the antenna support bracket.

I had ripped through 2 of the 3 antennas when cutting through the top adhesive. Not sure how anyone removes this display without ruining at least one of them.

I saw on Reddit this post: https://www.reddit.com/r/techsupportmacg...

It works perfectly! My wifi was one that was cut. It’s now made of aluminum foil and is pulling down 147Mbps and pushing 80.88Mbps up.

A ce stade il semble important de faire attention au micro. Pour ma part, il avait un résidu de colle entre celui-ci et le support à retirer.

On my device the mic is glued to the antenna board. I'd recommend to detach it's ribbon cable from the motherboard before removing the antenna board

what is this clear round plastic piece that came off with the display glue? cant add picture

-

-

crwdns2935267:0crwdne2935267:0Tweezers$4.99

-

Insert one point of a pair of pointed tweezers into a gap in the corner of the EMI shield covering the heat sink.

-

Use the tweezers to pry the EMI shield away from the motherboard as much as you can without bending it. Do not remove it yet.

-

-

-

Repeat the last step at various locations around the perimeter of the EMI shield covering the heat sink.

-

Remove the CPU shield.

-

-

-

Use a T3 Torx screwdriver to remove two screws from the heat sink:

-

One 2.4 mm screw along the top of the rectangular plate covering the battery.

-

One 2.2 mm screw along the bottom of the rectangular plate covering the battery

La première vis de 2,4 est une Torx 4, pour ce qui me concerne et non pas une Torx 3.

Attention la deuxième vis est bien une TORX 3

Remarque : La boite à outil "Essentiel electronics Toolkit - Grade B (ref EU145571-1)" ne contient pas l'embout T3

Pour ma part j'ai utilisé donc le T4 en forçant un peu. Pas cool ;-(

2.4 is not included in kit either I'm going mad I want to fix my surface pro but now I gotta go buy 2.4 and 2.2 torx screwdriver

-

-

-

Use a Phillips screwdriver to remove three 2.4 mm screws securing the fan.

-

Use a T5 Torx screwdriver to remove the final 4.4 mm screw securing in the fan cover.

These screws were in a different area on my Surface, Pro 4 bought at release. The fan was visible and attached to the heat sink. Remove the two torx screws on the fan housing. No need to remove the Philips head screws that secure the fan.

My Surface Pro 4 has a fan here. Remove the screws around the fan and the whole heatsink including the fan can now be lifted off. DO NOT try and remove the heatsink from the fan as it is glued on.

Sorry I’m super brand new to the game. I don’t know the difference between 1.5mm Torx T4 and 3.0mm Torx T4. I look under tools I need to buy, and the tool kits only say Torx T4 or T5, without the milimeters dimensions.

Je fais écho au commentaire de vennic, les longueurs indiqués en mm sont les longueurs des vis et n’impactent pas les tournevis à utiliser. Bien ranger les vis par longueur permets de mettre les bonnes vis aux bons endroits lors du remontage de l’appareil.

Cajuteq -

MInh Le Nguyen, the mm size refers to the length of the screws, not the size of the bit driver

Don’t forget to unplug the fan (if present) before yanking on the heat sink! It’s just a small grey clasp that needs to be lifted up.

The fan connector on mine was held in place by a white clamp on the side closest to the middle of the chassis. The long edge toward the middle flips up to vertical. That frees up the fan connector. Likewise for the black “wire” connector right beside it.

As previously mentioned, the fan should be disconnected (look at step 36) BEFORE you remove the fan/heat sink assembly. Ive done DOZENS of these repairs and the fan has always been part of the heat sink assembly.

I did all of this, now surface won't turn on. Any ideas?

-

-

-

Use a T5 Torx screwdriver to remove the heat sink screws surrounding the CPU in the following pattern, one turn at a time, until they're free.

-

Screw 1

-

Screw 2

-

Screw 3

-

Screw 4

These screws were T5 Torx in mine, not T3 as in the instructions.

T5 Torx screwdriver is correct.

T4 Torx for me.

What does one turn at a time mean?

One turn for the "red" screw, one for the orange, one for the yellow, then green and now again one turn red, orange, yellow, green ... This cross pattern distributes the pressure evenly .

VauWeh -

I think I need a T6 torx screw the screwdriver is not working for these screws

-

-

-

Use the flat end of a spudger to gently pry the heat sink straight up and off of the CPU.

Hallo, kurze Frage ist der Kühlkörper also die Kupferstücke innen hohl?

-

-

-

Insert the pointed end of a spudger into a screw hole in the fan shield and lift up to separate it from the fan.

The fan should be disconnected (look at step 36) BEFORE you remove the fan/heat sink assembly. Ive done DOZENS of these repairs and the fan has always been part of the heat sink assembly.

I'm not sure if adhesive was involved or if time and heat had caused the protective plastic film under the top section of fan to stick to the heat sink, but I had to use the Spudger to separate the heat sink from the plastic film to get it out.

These instructions were correct for my Surface. The fan cover was attached to the heatsink but the fan was not.

-

-

-

Carefully remove the heatsink.

Fan assembly may be taped to heat sink so fan screws and ribbon cable can be disconnected to remove as one with heat sink.

-

-

-

Gently slide the flat end of a spudger between the speaker wires and the motherboard until it is resting against the connector.

-

Carefully pry straight up on the speaker wire connector to disconnect it from the motherboard.

-

-

-

Use the flat end of a spudger to flip up the white plastic locking flap of the ZIF connector at the top-left corner of the motherboard.

-

Use the pointed end of a spudger to pull the cable out.

I broke this ZIF Connector. Can I have the name of this connector(what kind of this connector) to search to purchase for replacement. Please advise.

Or please advise for Power/Volume Button Cable Pinout to direct connect (Soldering/Wiring)

i broken that too, but i wonder if even you can purchase one, how can you solder it onto the board?! it is so tiny...

-

-

-

Use a T5 Torx screwdriver to remove the 3.3 mm screw securing the left speaker.

-

-

-

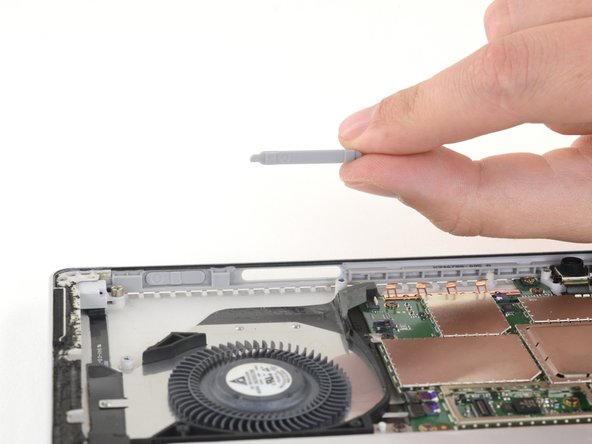

Grip the left speaker by the narrow section of the box and slide it back out of the chassis.

-

Remove the left speaker.

-

-

-

The volume and power buttons are now loose and may fall out. Make sure not to lose them.

-

-

-

Use the pointed end of a spudger to open the ZIF connector securing the fan to the motherboard.

-

Disconnect the fan cable.

-

-

-

Use a T3 Torx screwdriver to remove the following screws from the fan:

-

One 2.5 mm screw with coarse threads

-

Two 2.4 mm screws

-

-

-

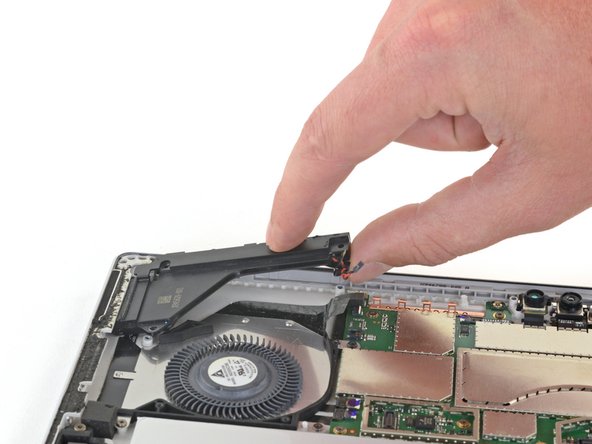

Use a spudger to lift one side of the fan.

-

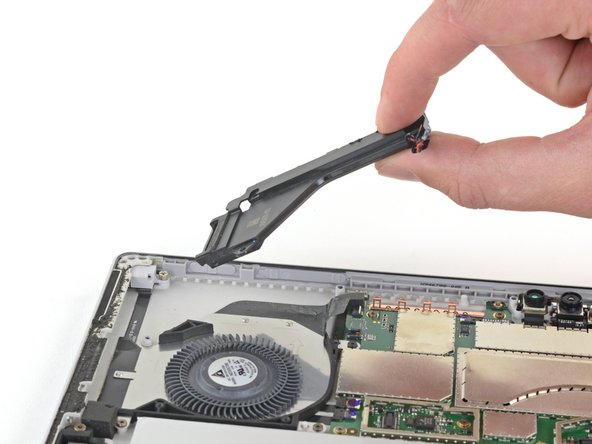

Pick up the fan and remove it.

-

To reassemble your device, follow the above steps in reverse order.

Take your e-waste to an R2 or e-Stewards certified recycler.

Repair didn’t go as planned? Try some basic troubleshooting, or ask our Answers community for help.

To reassemble your device, follow the above steps in reverse order.

Take your e-waste to an R2 or e-Stewards certified recycler.

Repair didn’t go as planned? Try some basic troubleshooting, or ask our Answers community for help.

crwdns2935221:0crwdne2935221:0

crwdns2935229:06crwdne2935229:0

crwdns2947412:03crwdne2947412:0

I realize tis is a older post but, I have a strange one here, I've opened up the surface pro (model number 1724) screen flickering and found the Fan was missing. On closer inspection, it appears there is no fan header, the land points are there just no connector. Has anyone every had this before?

Yours is probably an m3-6Y30 fanless version, just like mine. I was thinking of adding a fan to make it cooler, but it seems that the fanless version does not have the fan connector soldered in place yet.

I really appreciate the effort that went into describing this process.

The SP series is plagued with throttling issues, lack of fans, and where fans are present, they are too small or fail after 2-3 years.

Which unless you go through a risky (and for many not really possible) routine such as this, you basically have $1,200 worth of - otherwise perfectly good tech - to put in the bin.

My SP4 (i7) failed for this reason. My friends i5 went the same way. My father in law had the Celeron version, and it's still going. It's incredibly slow even when not throttled, but at least it works.

Then we found out that's because the Celeron version... doesn't come with a fan (so no fan to break down)

I sold mine for a 6th of what I bought it for and moved to something "user maintainable". My Dell's fan did indeed suffer the same fate after less than 2 years - I fixed it in 10 minutes with a Philips head screwdriver. The new fan cost... $6.99 from Amazon. :)

If I have a screen protector on the screen should I remove it? Will it interfere with the heating process?

IronJoker - crwdns2934203:0crwdne2934203:0

I was wondering if I should put a screen protector on to help keep the screen from cracking???

Kevin - crwdns2934203:0crwdne2934203:0