crwdns2935425:06crwdne2935425:0

crwdns2931653:06crwdne2931653:0

-

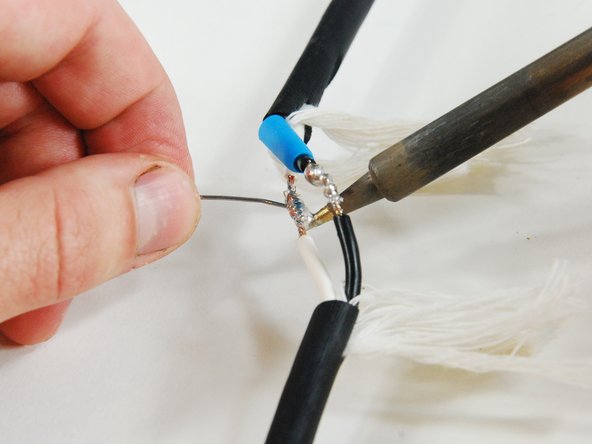

Solder the wires together.

-

Put a little bit of solder on the tip of the iron.

-

Hold the iron to the wire, and add the solder to the joint. When the wire gets hot enough, the solder will melt and suck itself into the wire.

-

Add enough solder and move the iron around enough to make the entire joint silver colored.

-

Once the wire is cool to the touch slide the heat shrink so it covers the joint.

crwdns2944171:0crwdnd2944171:0crwdnd2944171:0crwdnd2944171:0crwdne2944171:0