crwdns2915892:0crwdne2915892:0

The drill press spindle turns inside the quill using several bearings. After a lot of use, these bearings can wear out and need to be replaced.

This guide will show you how to replace those bearings.

crwdns2942213:0crwdne2942213:0

-

-

Remove the chuck from the spindle and support the quill to prevent it from dropping uncontrollably when the spring tension is released.

-

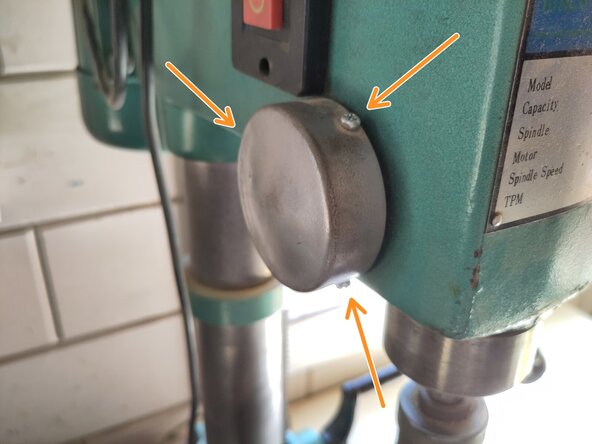

Remove the 3 bolts that hold the spring cover in place and remove the cover.

-

Turn the spring lock screw left to release the spring tension.

-

-

-

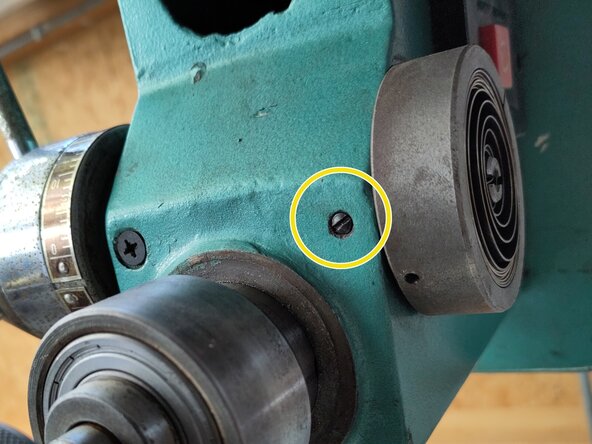

Pull out the feed lever pinion.

-

Remove the supports and remove the quill from the drill press frame.

-

-

-

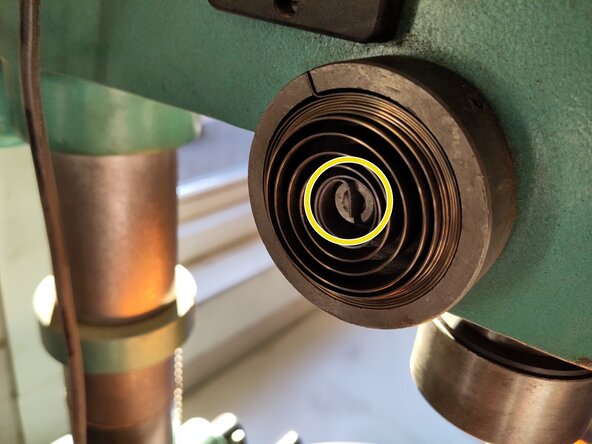

Remove the snap ring holding the top bearing in place.

-

Use the press to press the spindle from the quill.

-

-

-

-

The bearings are press fit into the quill, remove the bearings with the bearing removal tool.

-

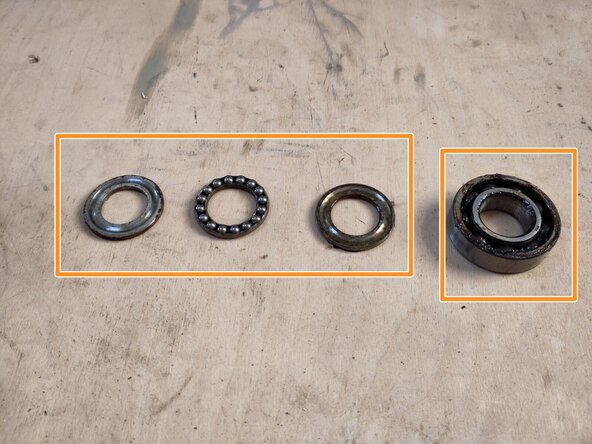

The bottom bearings consists of a thrust bearing on top of "regular" deep groove ball bearing.

-

-

-

Clean the quill and insert the thrust bearing.

-

Press in the bottom bearing on top of the thrust bearing.

-

Next, press in the top bearing.

-

-

-

Slide the spindle back into the quill.

-

Use the press to press the spindle fully into the quill. Make sure the top bearing is not pressed out again by supporting it from beneath.

-

Add the snap ring back on top of the quill.

-

-

-

Insert the quill back into the frame.

-

While pushing and holding the quill up, slide the feed lever pinion back in connecting with the quill rack.

-

Insert the end of the pinion into the spiral spring.

-

Complete the repair by tensioning the spring. Refer to the separate guide for detailed instructions.