Circuit Board traces are fried, looking for suggestions

Hello all, first time posting to these forums. I've got a general Circuit Board fixing question, and a Ribbon that's been cut.

TOP

BACK, also rotated 180 deg so "Photo Bottom" of the circuit board is the same on each photo.

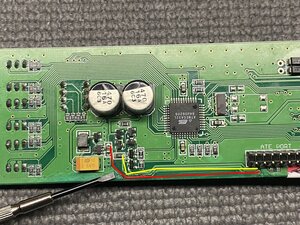

So looks like some water/snow/ice got in and fried the circuit board. The location is indicated on the TOP image by the screwdriver. It look like the Capacitor traces jumped across to the next and caused a short. Well, those traces are now completely dead. Also, the Capacitors I believe to be fried, because the whole unit won't function. The other trace that is fried, runs to a test port on the right side, and otherwise through a series of Resistors and Transistors, they all seem fine; also visually nothing else looks "shiny" or singed.

So I think it is just the Capacitors that I need to replace. Since they are surface mounted, I am looking for alternative ways to achieve this.

- TOP photo you can see 3 THRU holes in the board, I figure I could solder the Cathode through these. (on the BACK photo, these are a little "Upwards" from the screwdriver)

- However, looking for the Anode connection point, and the current traces don't run very far. Would it be advisable to drill through where the screwdriver is on TOP photo, and remove (scratch/sand away) any of the trace on the BACK of the unit?

This got cut by a razor blade (maybe by me, maybe not), and wondering what a good way to go about reattaching the leads in the most permanent way. It's a surface button, under a sticker and you can see the housing. Ideally I'd like to retain the Ribbon style, as if the button part of the label cracks open (due to over use) it will prevent water from entering the unit. (These units are used outside).

- I was thinking just use some sandpaper to expose the leads on each part, then carefully lay some super glue on the non-contact parts and press together. Then case in Clear Nail polish.

EDIT: Re-uploaded images for full clarity

crwdns2934109:0crwdne2934109:0

1

1

940

940  2,4crwdns2936485:0crwdne2936485:0

2,4crwdns2936485:0crwdne2936485:0