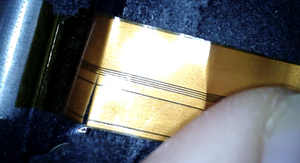

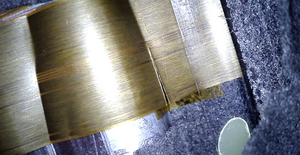

Actually, those flex cables are repairable, as long as you understand they will lose flexibility, so if the break is in a section that bends and flexes constantly, the repair may not hold. But if it's done on a stationary cable that doesn't have to bend or move, it should be fine. I'm only seeing somewhere around four cut traces that would have to be reconnected, so it should be quite doable.

Basically, you have to reconnect the broken copper traces. That involves scraping off the top insulating layer to get down to the actual metal, at which point you now have a place to solder to. Apply flux and bridge the gap between the cut with solder. Here's a video showing the basic process.

How I Fixed A Broken FLEX CABLE INSTANTLY! - Mr Biomedical - YouTube

You can actually make the repair more secure by bridging the gap with wire embedded in the solder, but as I mentioned, for a stationary flex cable, the solder alone should be sufficient. Although the use of UV cured solder mask is a good idea, I suspect covering it with something like Kapton tape would work just as well.

crwdns2934105:0crwdne2934105:0

crwdns2934113:0crwdne2934113:0

crwdns2915270:0crwdne2915270:0

crwdns2889612:0crwdne2889612:0

2

2

2  1

1

103

103

crwdns2947414:01crwdne2947414:0

I have the same problem and I agree with you. Sure it's possible to solder flex cables, but these traces are so small i see no chance on doing that.

crwdns2934271:0crwdnd2934271:0 tungsten crwdne2934271:0