Just happened to us! I'm very grateful to the OP and responders for all the intel!

I'm mechanically enough inclined, and will probably use Loctite 640 sleeve retainer and not go to the extent of pinning. Mainly I don't want to tear the whole thing down to get the shaft out.

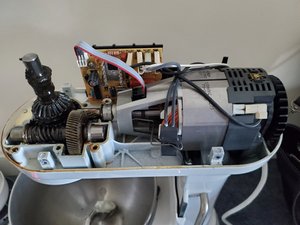

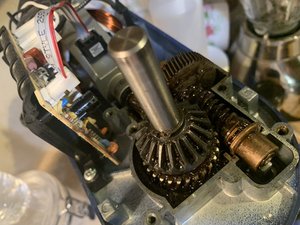

Does anyone know how far the ring gear is supposed to be up into the housing?

I see that an earlier post mentioned their ring gear was coming out along with the planetary head. Mine shows about 1/16" below the housing, so it may be coming out as well. There appears to be quite a bit of room above the gear. Wondering if I should try to tap it all the way home, or just what?

Update:

I called Kitchenaid, and not surprisingly they have never heard of this issue! So much for an honest company! But they did provide me a phone number for a repair facility, which I called.

I spoke with a friendly helpful appliance repair tech. He said that the shaft would have to be removed because there is vertical play, and if you attempt to tap the planetary housing into place (as I was going to do), then the shaft (splined end) will not fully seat in its socket.

Remove the shaft and use a block of wood to tap it back into its socket (common sense, if you're re-using the shaft, to avoid damaging the top end).

Also the ring gear gets tapped all the way up into the recess, until it bottoms out.

Also advises to check the gear housing cover carefully if it is the earlier plastic (vs later aluminum), for cracking or broken-off locating pin.

On a possibly related note, does anyone recognize these 2 small metal pieces? After doing the planetary head repair I decided to adjust the bowl-lift height (Pro 600), and at some point I noticed these lying on the counter top. Nobody in the household admits to placing them there. So I'm assuming they fell off the mixer at some point, but no idea...

crwdns2934105:0crwdne2934105:0

crwdns2934113:0crwdne2934113:0

crwdns2915270:0crwdne2915270:0

crwdns2889612:0crwdne2889612:0

0

2

2  2

2  359

359

crwdns2944067:014crwdne2944067:0

You likely lost the c clip on your vertical shafts in the gear box.

crwdns2934271:0crwdnd2934271:0 Valthor crwdne2934271:0

I don't see a clip on the parts list. Mine has done the same thing. Frustrating.

quinn47 did you get yours repaired? what did you do??

crwdns2934271:0crwdnd2934271:0 Rebecca Abraham crwdne2934271:0

Any idea where to get a replacement part for this fix? I had the same issue.

crwdns2934271:0crwdnd2934271:0 brodie_wise crwdne2934271:0

THERE IS NO CLIP ON THE 600. So, did anyone actually fix this?

crwdns2934271:0crwdnd2934271:0 DerbyGirl Swan crwdne2934271:0

I had the same problem. It appears that the shaft which goes into the housing is splined and the aluminum housing spline has been stripped out. I’d take the upper housing apart. Remove the clip to drop the spine shaft out. Next use a metallic epoxy to epoxy the spline shaft back into the housing . Make sure the housing where the spine shaft is really clean. Leave to set and then reassemble. Use a good epoxy that is used to build up gear journals usually found into automotive stores. Otherwise buy a new housing.

Good luck

crwdns2934271:0crwdnd2934271:0 Harold karcher crwdne2934271:0

crwdns2934275:09crwdne2934275:0