crwdns2935425:021crwdne2935425:0

-

The parts of the Lower Dials are fixed to the shaft using tapered pins.

-

During installation, the part is placed on the shaft, held in place, and then a hole is drilled through the part and the shaft using a taper pin drill bit.

-

Next, a taper pin is inserted into the hole until it stops, then it is pressed in with an arbor press. The pin is then cut or ground off.

-

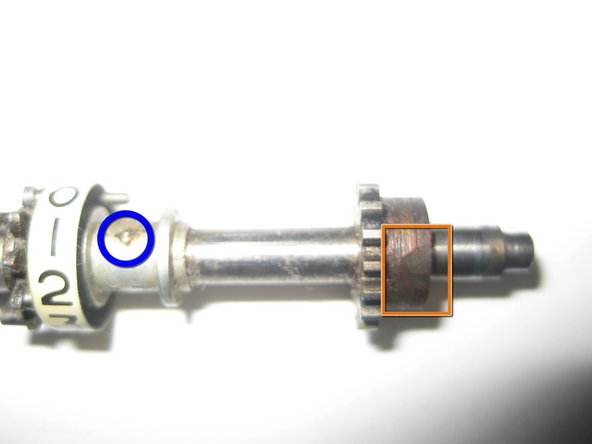

Indicated is a hole in the Lower Dials driver gear for its taper pin.

-

In this dial spacer, the taper pin is clearly visible.

-

Rotating the shaft to the other side, we can see the over-enthusiastic application of a grinding head applied to the other end of the taper pin on the driver gear.

-

Meanwhile, the taper pin is again clearly visible on the dial spacer.

crwdns2944171:0crwdnd2944171:0crwdnd2944171:0crwdnd2944171:0crwdne2944171:0