crwdns2935425:05crwdne2935425:0

crwdns2931653:05crwdne2931653:0

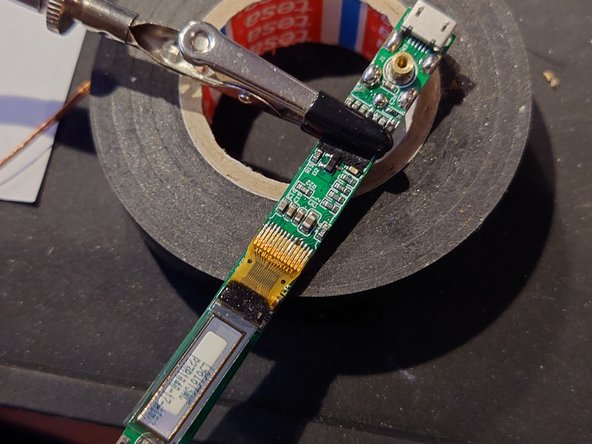

Soldering the display module

-

Put a line of flux paste over pads and flat cable end.

-

Take the display module with face side down. Put the flat cable on cleaned pads on circuit board. Arrange the cable over pads to left free pad area a little less than 1mm from the left side (in second photo).

-

Set soldering iron temperature to 270C (520F). Tin the soldering iron and solder the cable to the board.

crwdns2944171:0crwdnd2944171:0crwdnd2944171:0crwdnd2944171:0crwdne2944171:0