crwdns2935425:04crwdne2935425:0

crwdns2931653:04crwdne2931653:0

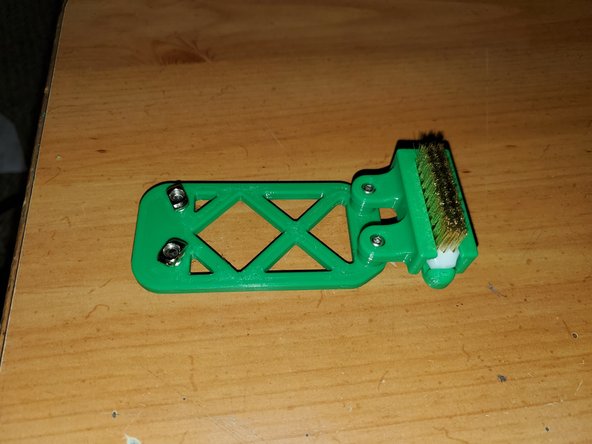

Nozzle Brush

-

Press in 2x M3 NYLOC nuts into the bottom of the Nozzle Brush Base.

-

Thread in 2x M3x16 button head screws through the Nozzle Brush Holder into the Nozzle Brush Base.

-

Insert the brush head into the holder.

-

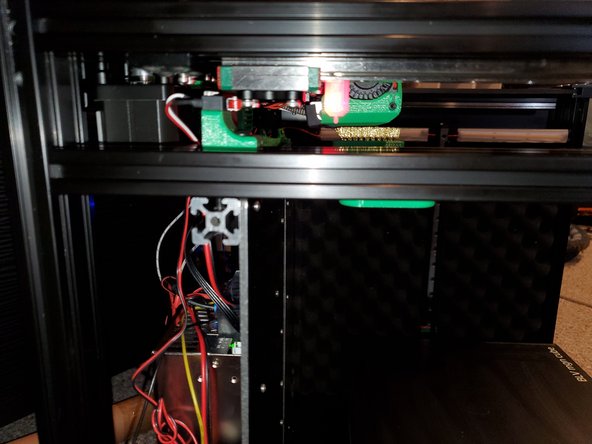

Mount the Nozzle Brush assembly to the frame with 2x M5x10 button head screws and 2x M5 T-nuts

-

When the nozzle is at X min and Y max the nozzle should be a few mm behind the brush. This is to ensure during the wipe movements the X mount isn't hitting the endstop

crwdns2944171:0crwdnd2944171:0crwdnd2944171:0crwdnd2944171:0crwdne2944171:0