crwdns2915892:0crwdne2915892:0

Use this guide to replace your epee blade wiring.

crwdns2942213:0crwdne2942213:0

-

-

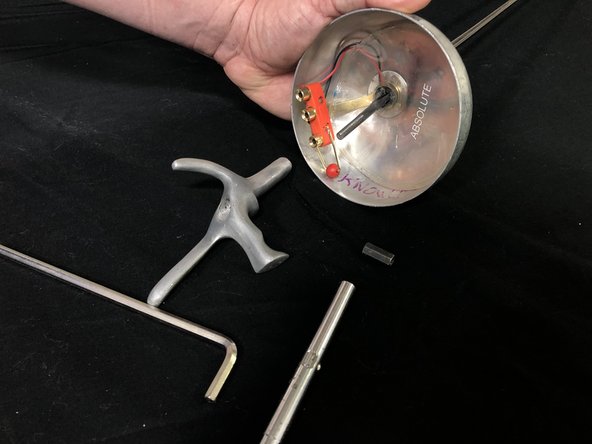

Use an Allen wrench to remove the nut in the center of your weapon handle and pull the handle off of the blade.

-

-

-

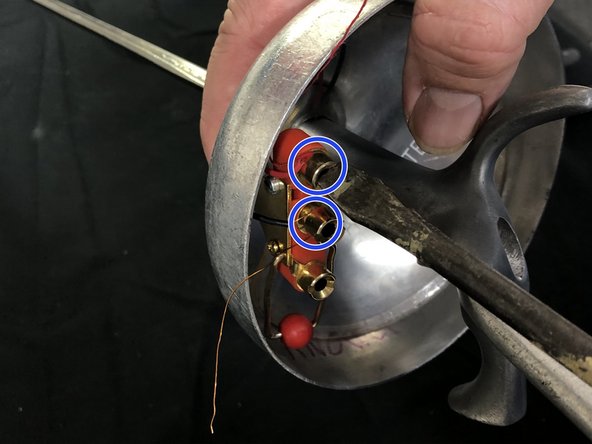

With a flathead screwdriver, gently loosen the two bodycord sockets closest to each other.

-

With the bodycord sockets loosened, gently remove the black and red wires wrapped around them.

-

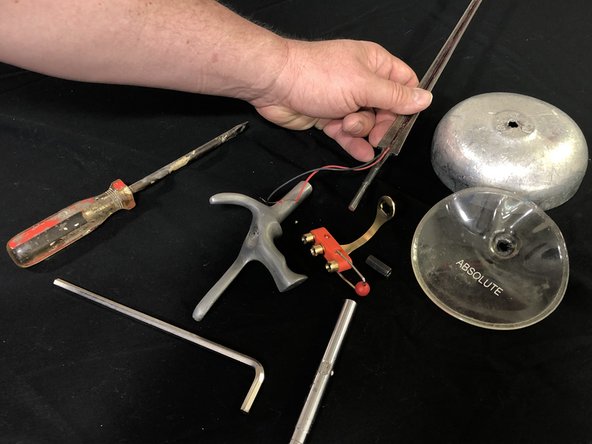

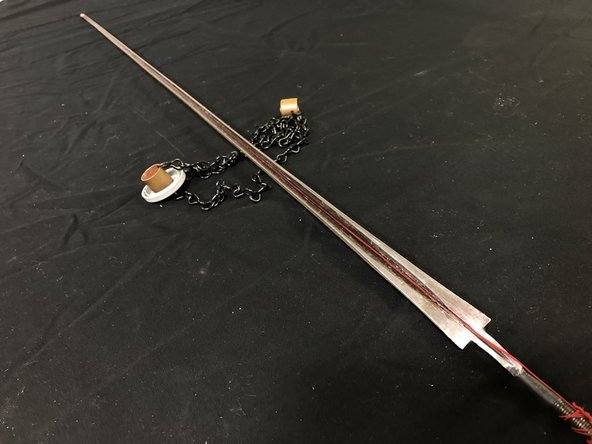

Once the wires have been removed, the bodycord socket and beltguard can be removed from the blade, leaving the blade bare.

-

-

-

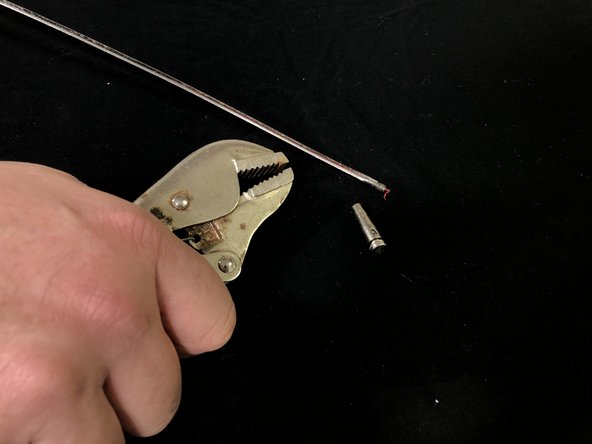

With the curved jaw locking pliers, gently unscrew and remove the tip of the blade.

-

-

-

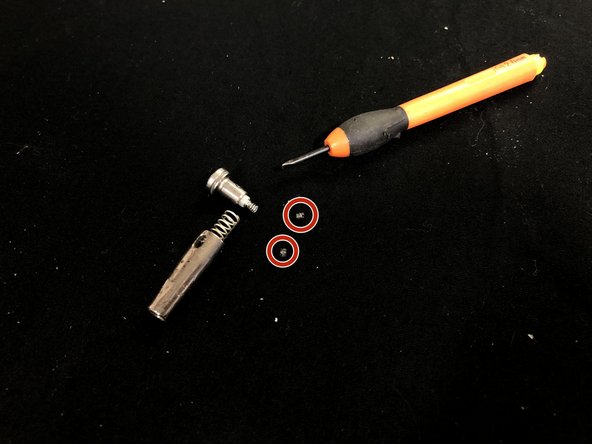

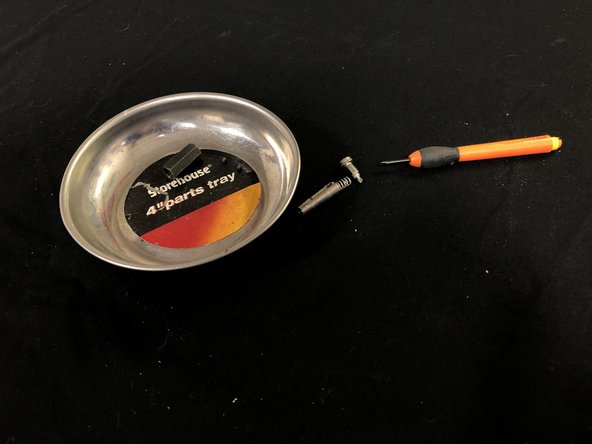

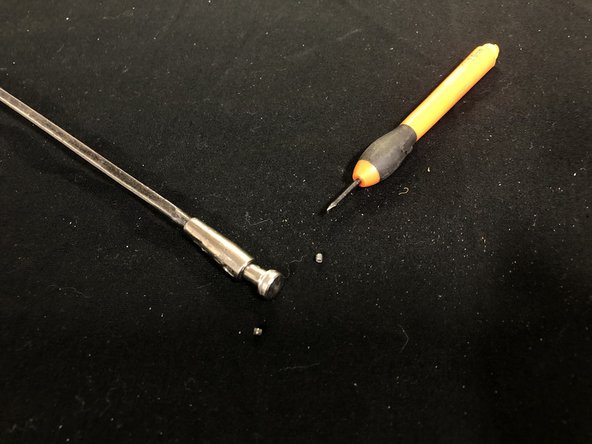

Remove the two tiny screws on either side of the tip removed earlier.

-

-

-

Remove the leftover wire cap from inside the tip by sticking a screwdriver through the barrel of the tip.

-

-

-

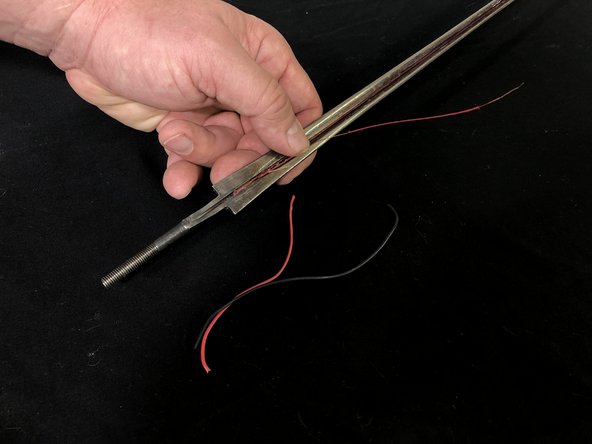

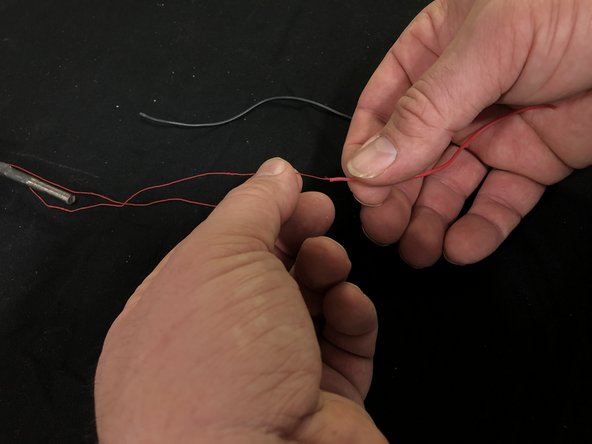

Pull the bright red and black rubber insulation off of the end of the wires at the base of the blade. Save these for later.

-

-

-

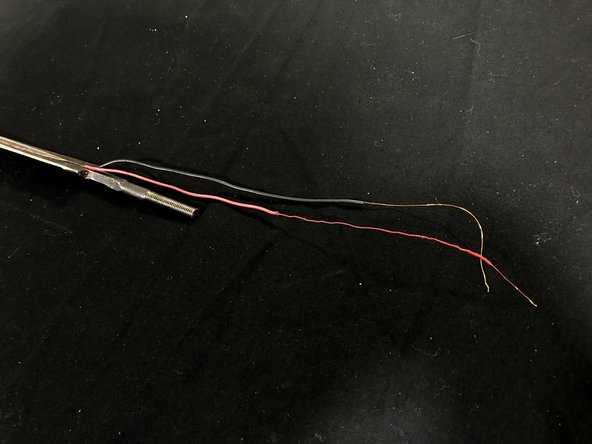

Remove the wire from the length of the blade by pulling it away.

-

-

-

-

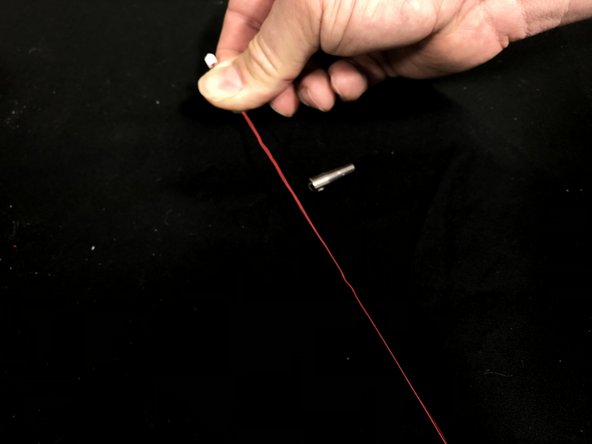

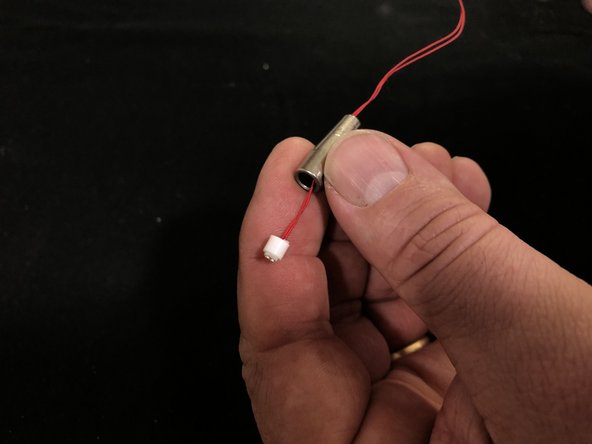

Unravel the replacement blade wire and feed the end without the white cap through the top of the tip barrel.

-

-

-

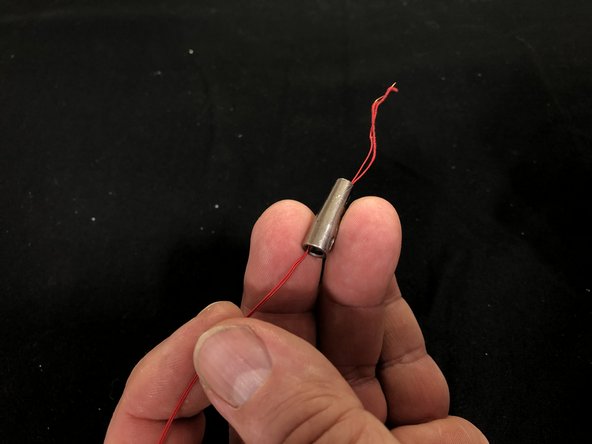

With the wire fed through the tip, tighten the tip barrel back onto the blade and pull the wire down the length of the blade.

-

Once the barrel has been tightened onto the blade, use a screwdriver to push the white cap of the wire down into the barrel.

-

-

-

Once the wire has been pulled down the blade, wrap the excess around the bottom of the blade to hold the wire in place.

-

-

-

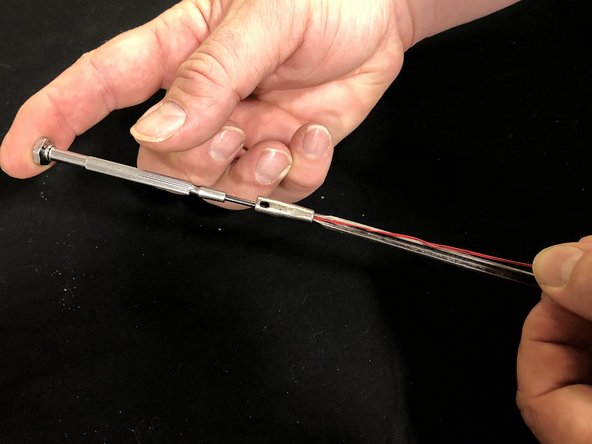

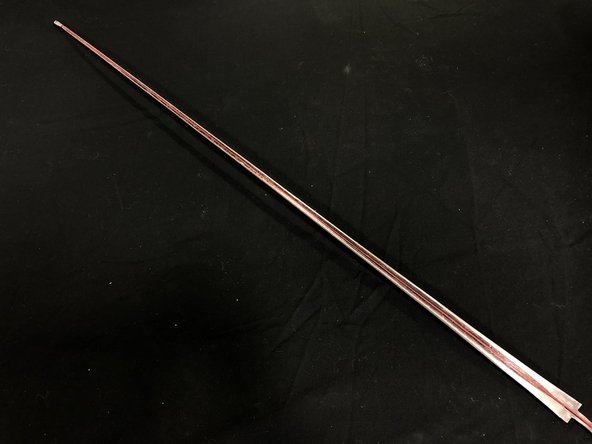

Take the re-wiring rig and place the base of the blade in one end and the tip in the other. The blade will bend into a bow-like shape and pull the wire taut.

-

-

-

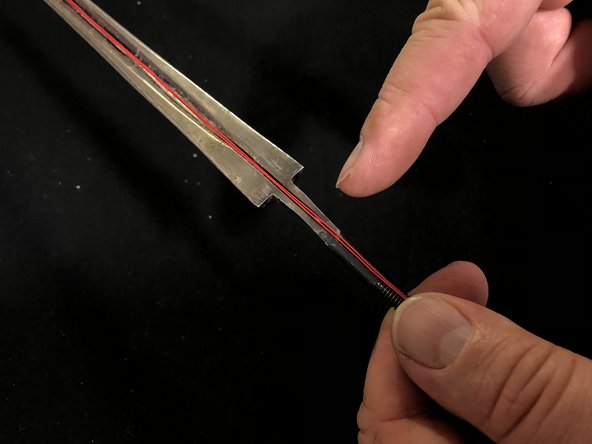

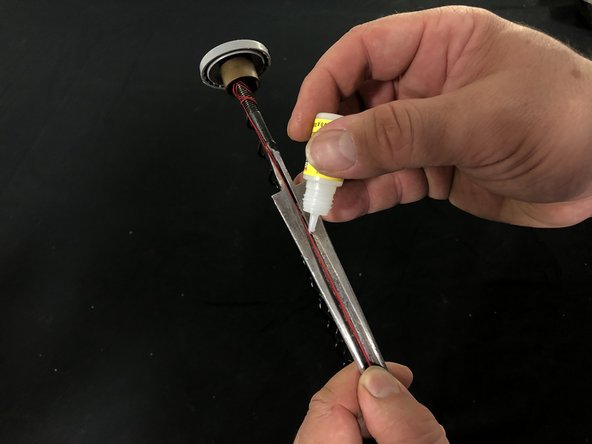

Carefully drip glue over the top of the wire in the blade crevice, allowing gravity to pull the glue down the length of the blade.

-

After allowing the glue to run down one half of the blade, let it dry, then flip the blade upside down and run the glue down the other half.

-

-

-

Once the glue has dried, undo the tied wire at the end of the blade and slide on the rubber insulators that were pulled off earlier.

-

-

-

Slide the rubber insulators up to the base of the blade so that it touches the glued portion of the wire.

-

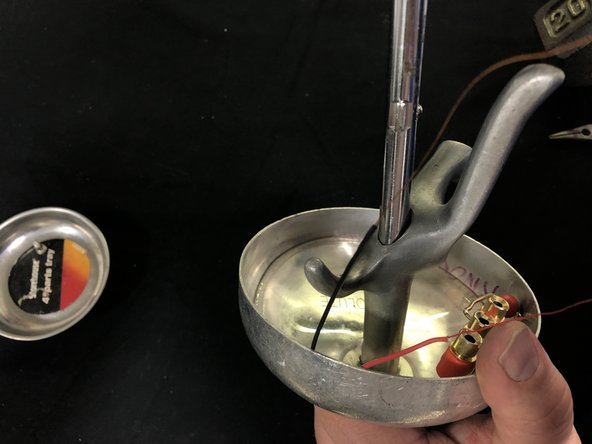

Slide the guard and bodycord socket back onto the handle of the blade.

-

-

-

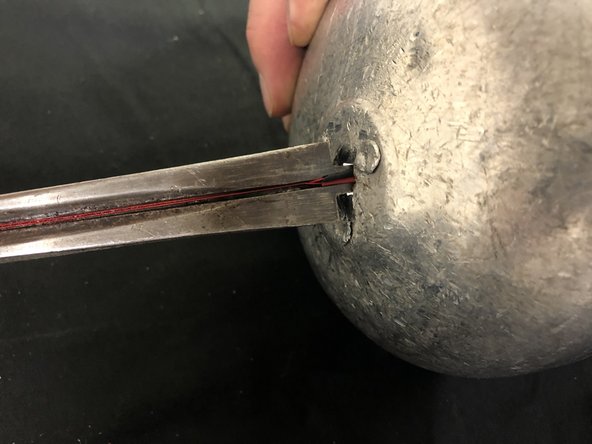

Place the handle back onto the blade, ensuring that the insulated wire runs through the small notch located at the end of the handle.

-

Replace and tighten the nut in the center of the handle with an Allen wrench.

-

-

-

Take a pair of scissors and gently scrape the non-insulated end of the wire sticking out from the handle to remove the metal and fabric coatings.

-

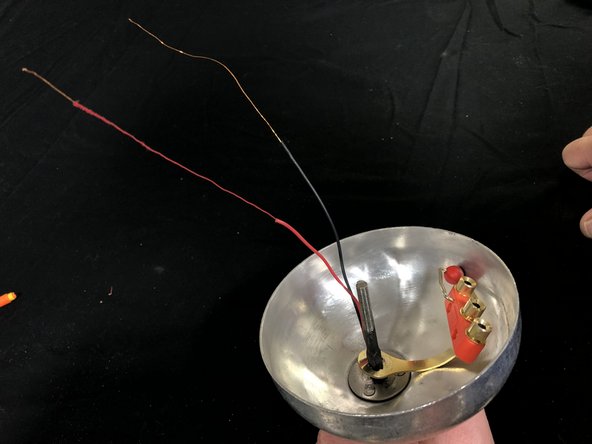

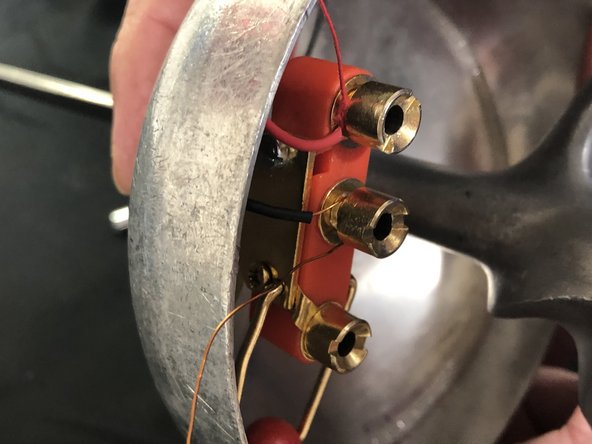

Once the coatings have been scraped from both wires, wrap one wire around each of the socket prongs that are closest to each other.

-

Tighten the socket prongs with a screwdriver.

-

-

-

Once the wires have been wrapped around and the socket prongs have been tightened, trim off any excess wire.

-

-

-

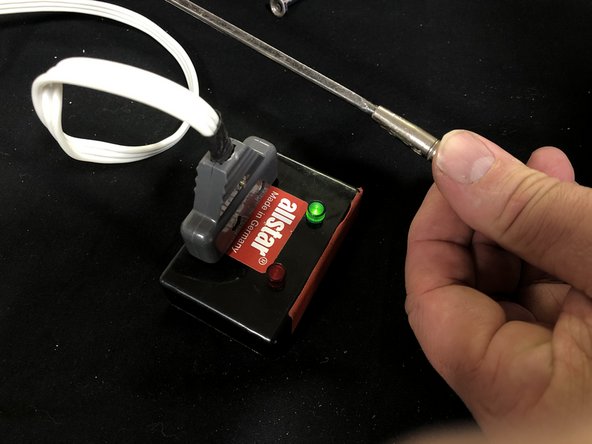

To check that the repair has been done correctly, connect the epee to an Absolute Fencing testing box with a bodycord.

-

Once connected, stick the tip into the tip barrel as far as it will go. The box will light up green if the re-wiring has been done properly.

-

-

-

Place the tip spring and the tip itself back into the tip barrel and replace the two small screws removed earlier.

-

Your epee blade should now have a functioning wire.

Your epee blade should now have a functioning wire.

crwdns2935221:0crwdne2935221:0

crwdns2935227:0crwdne2935227:0

crwdns2947410:01crwdne2947410:0

Hi. The blades I've been rewiring keep having their wires pop out at the middle section of the blade. I've tried switching glues but the problem is still the same. I was wondering if its because my fencing jig bends the blade too much when I glue on the wire, causing excessive length of wires when the blade becomes straight again?

If so, does that mean my blade only needs to be partially bend when I glue the wire? Not too bendy?