crwdns2915892:0crwdne2915892:0

Prerequisite-only! This guide is part of another procedure and is not meant to be used alone.

Follow this guide to separate the motor from the crankcase on a Wacker BS50-4AS REV 101 (2019) Vibrator/Rammer to perform internal repairs.

crwdns2942213:0crwdne2942213:0

-

-

Firmly grip the base of the spark plug wire's connector and pull it away from the spark plug to disconnect it.

-

-

-

Use a 1-1/16 inch socket to break loose the oil sight gauge near the bottom of the device.

-

-

-

Lay the device down horizontally with the oil sight gauge facing down.

-

Position a shallow oil drain pan underneath the sight gauge.

-

-

-

Remove the oil sight gauge.

-

Let the oil drain until drips are infrequent.

-

Replace and retighten the oil sight gauge.

-

-

-

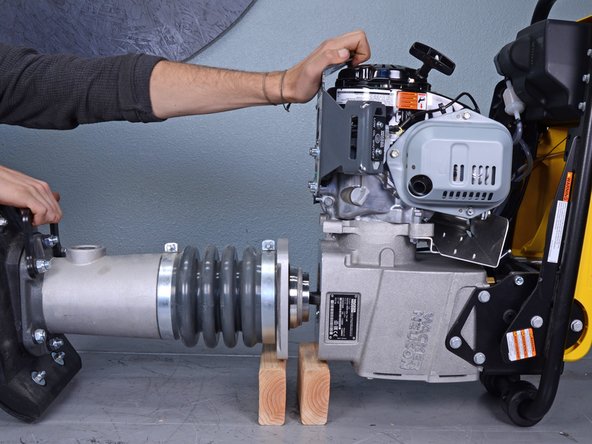

Flip the device onto the work surface such that the motor and handles face up.

-

Place two separate blocks of wood underneath the seam between the leg assembly and crankcase.

-

-

-

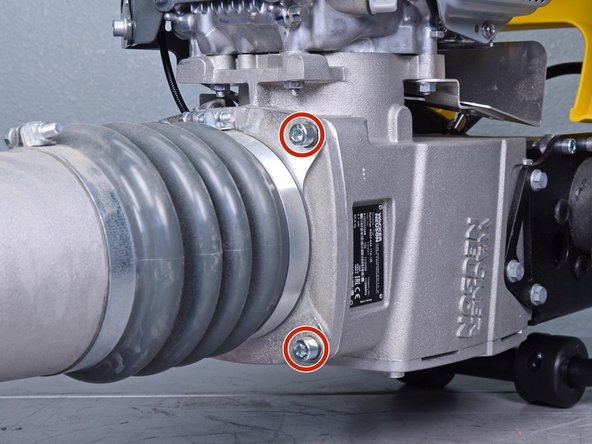

Use an 8 mm hex key socket to remove the four bolts securing the leg's guiding cylinder to the crankcase.

-

-

-

Pull the leg assembly away from the rest of the device.

-

-

-

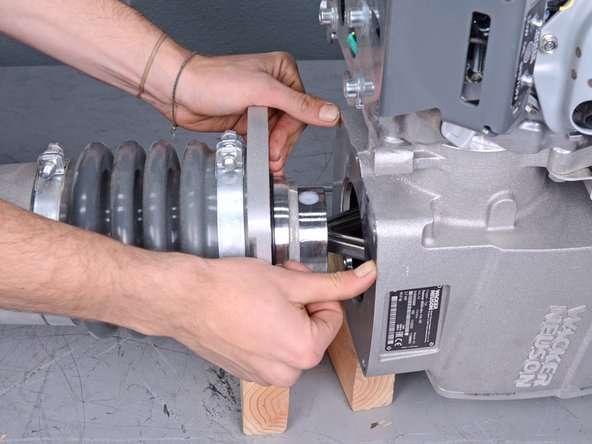

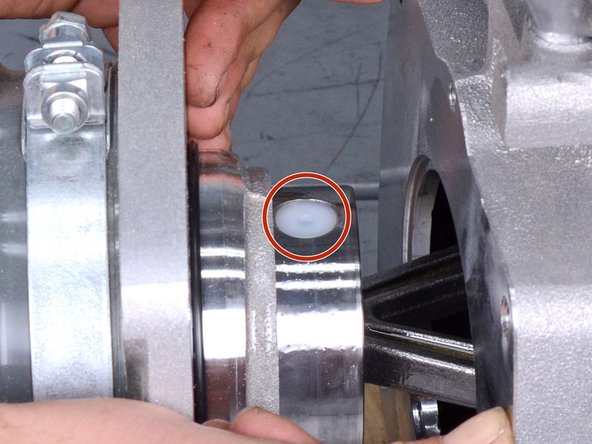

Continue to separate the two halves by compressing the bellows until the nylon plug covering the piston pin is visible.

-

-

-

-

Use an appropriately-sized punch and a ball-peen hammer to tap the pin out of its hole on the guide piston until it is no longer securing the connecting rod.

-

-

-

Remove the leg assembly from the crankcase.

-

-

-

Use a punch and hammer to tap the pin out of the guide piston.

-

-

-

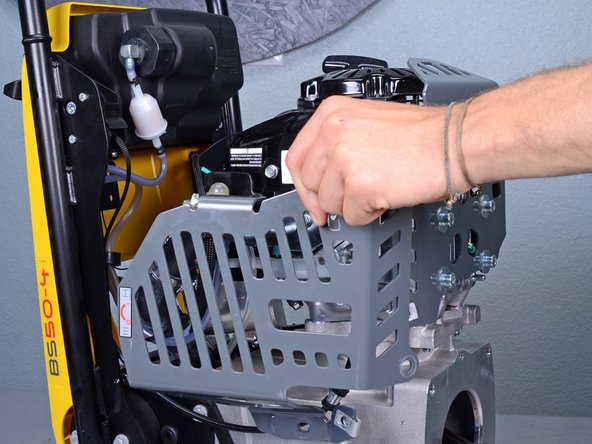

Use wood blocks to support the device on the work surface, motor facing up.

-

-

-

Use a 6 mm hex socket to remove the engine guard bolt securing the cable guide.

-

-

-

Pull the cable guide away from the engine guard.

-

-

-

Use a 6 mm hex socket to remove the three remaining bolts securing the engine guard: two on the outer edge and one near the crankcase.

-

-

-

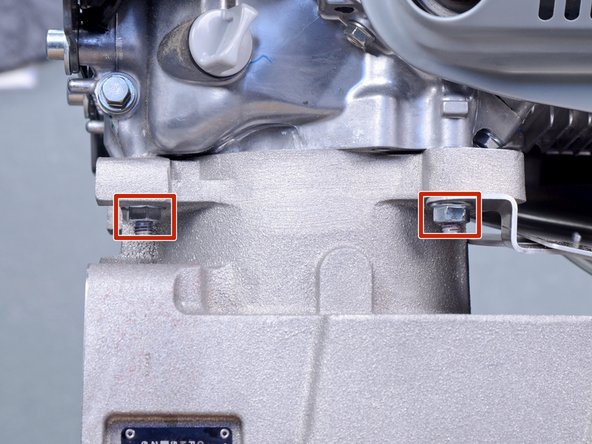

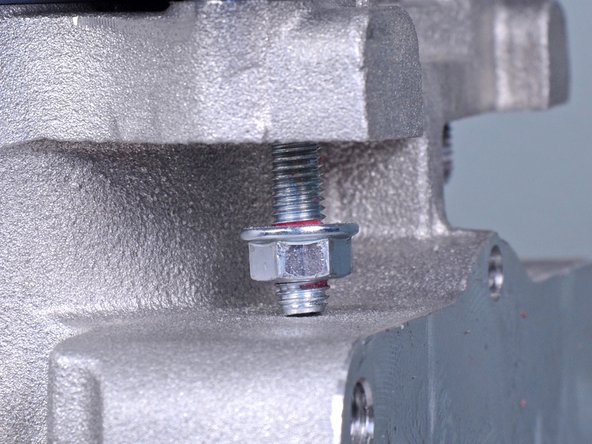

Use a 13 mm wrench to remove the four nuts securing the motor to the crankcase, two on each side.

-

-

-

Use a 10 mm socket to remove the bolt securing the muffler shroud.

-

-

-

Lower the muffler shroud away from the motor, down onto the crankcase.

-

-

-

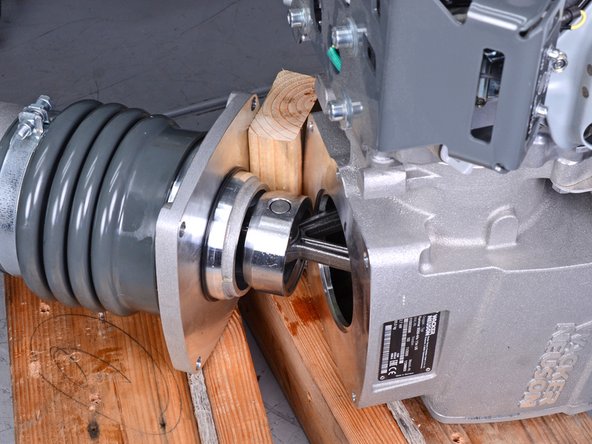

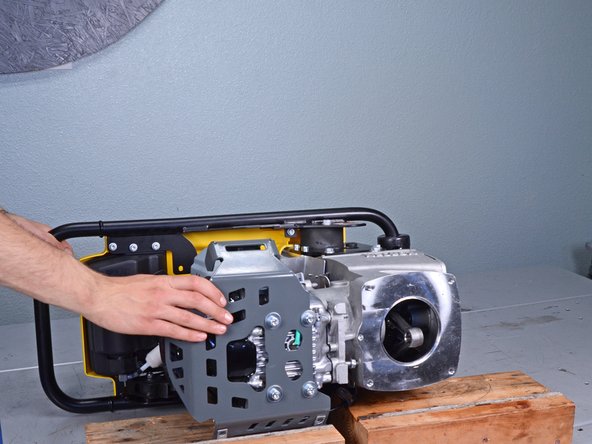

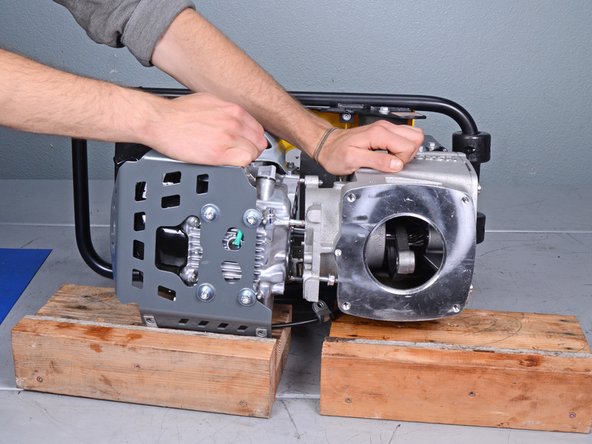

Tilt the device down onto its side, supporting both the crankcase and motor with blocks of wood.

-

-

-

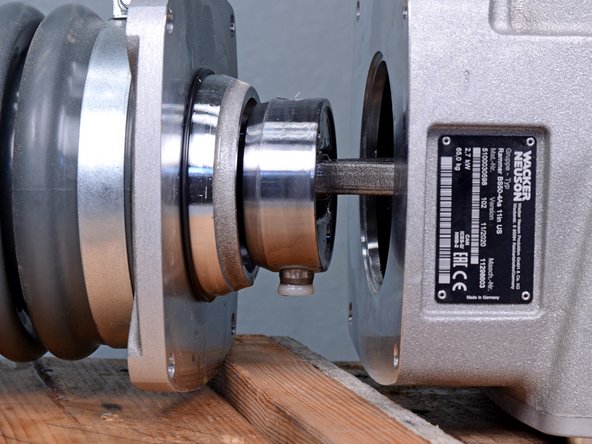

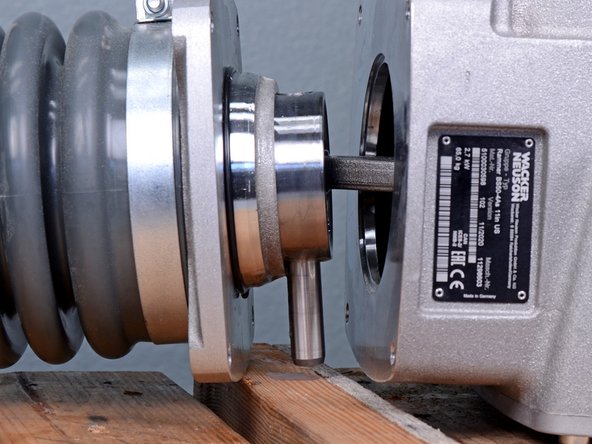

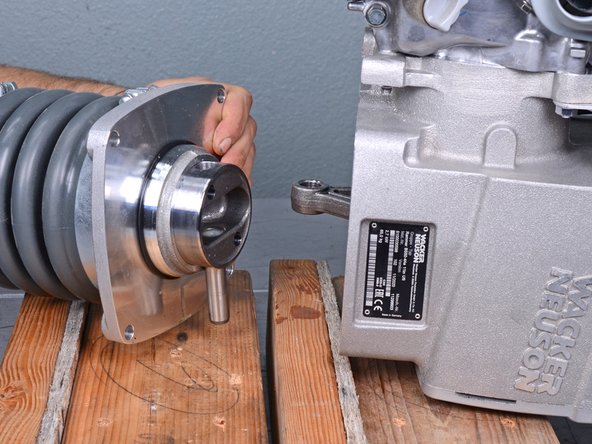

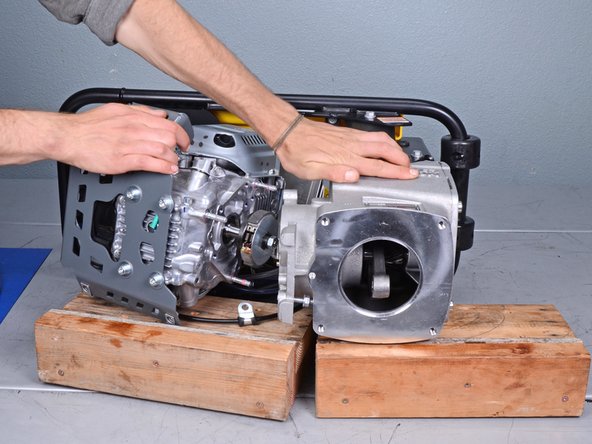

Hold the crankcase steady and pull the motor directly away from it.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.