crwdns2915892:0crwdne2915892:0

This guide will show you how to replace the diaphragm assembly. A faulty diaphragm assembly can lead to a few different issues including irregular shaking, grinding, or leaking grease.

crwdns2942213:0crwdne2942213:0

-

-

Remove the ten 19mm T20 Torx screws shown in red.

-

-

-

Remove the red Housing Assembly by lifting it up off of the tool.

-

-

-

Remove the two 10mm T-10 Torx screws that attach the top brush holders to the motor housing.

-

Remove the two 10mm T-10 Torx screws that attach the bottom brush holders to the motor housing.

-

-

-

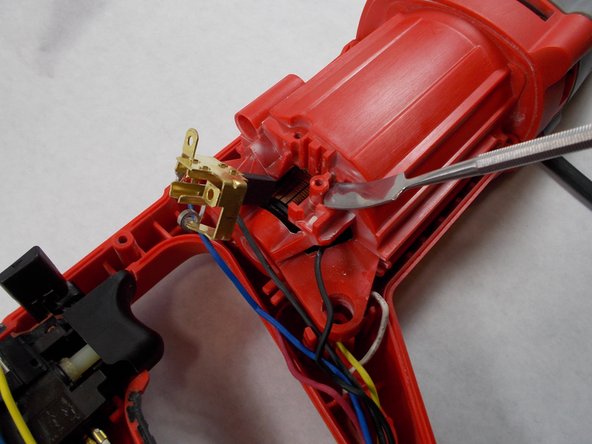

Using a metal spudger, pry off each brush holder.

-

-

-

Remove the four 37mm T20 Torx screws shown in red.

-

-

-

-

Pull the front portion of the tool out from the motor housing.

-

-

-

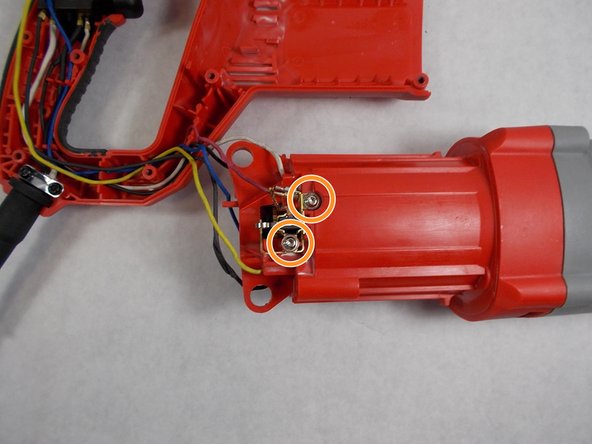

Remove the two 11.5mm T10 Torx screws shown in red.

-

-

-

Pull the 120V armature assembly out of the diaphragm assembly.

-

-

-

Using a metal spudger, pry the diaphgram assembly out of the gear case.

-

-

-

Now that you have loosened the diaphragm, you can now pull it out of the gear case.

-

-

-

After removing some grease (if needed), remove the two 15mm T20 Torx screws shown in red.

-

-

-

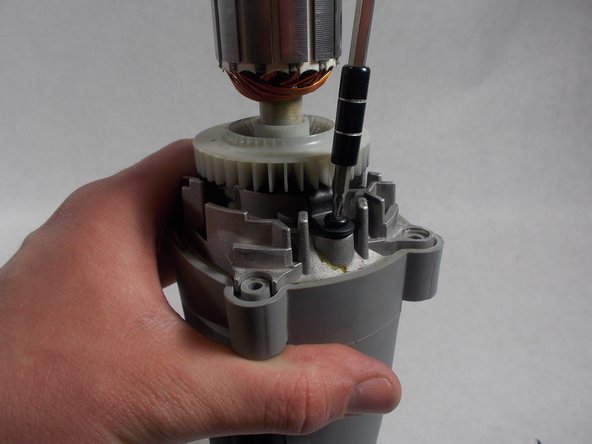

Now pull the reduction gear assembly up and out of the diaphragm.

-

-

-

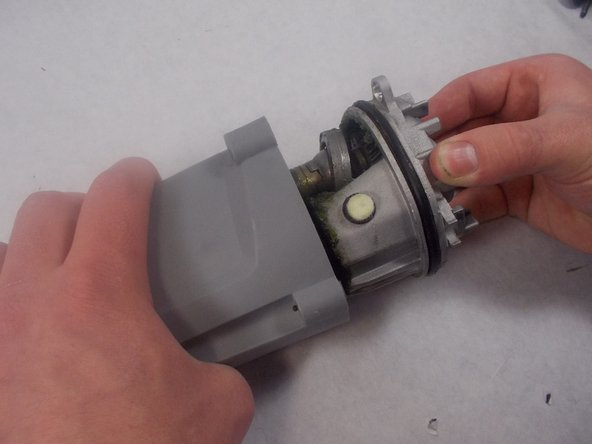

Remove the metal piston from the diaphragm assembly.

-

-

-

Using a metal spudger, pry the o-ring off of the assembly.

-

To reassemble your device, follow these instructions in reverse order.

crwdns2935221:0crwdne2935221:0

crwdns2935229:02crwdne2935229:0

crwdns2947410:01crwdne2947410:0

to reasemble .

Which is the correct position of the Shift knob assembly ?