crwdns2915892:0crwdne2915892:0

Deterioration of the grindstone is one of the most common issues with the Landis Universal Cylindrical Grinder. Because these machines are so old, there is little maintenance or repair documentation available. This guide will show you how to replace the grindstone on the machine and avoid the costs of hiring an on-site specialist.

crwdns2942213:0crwdne2942213:0

-

-

Lift the yellow guard up to unlock the grindstone access panel.

-

-

-

Pull the access panel outward to expose the grindstone.

-

-

-

-

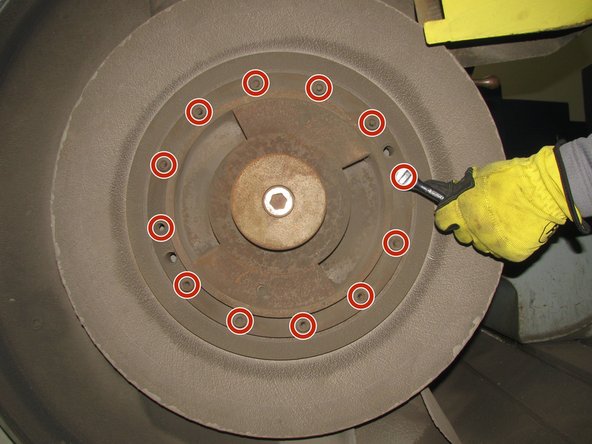

Remove the twelve bolts securing the grindstone using a ratchet with a 5/16 Hex bit.

-

-

-

Gently remove the steel hub from the grindstone spindle.

-

-

-

Carefully remove the grindstone itself from the spindle, making sure to support it from the top and inner ring.

-

-

-

Softly sand the hub with 600-grit sandpaper or a wire brush to remove any surface rust.

-

To reassemble your device, follow these instructions in reverse order starting from step 6.

To reassemble your device, follow these instructions in reverse order starting from step 6.

crwdns2935221:0crwdne2935221:0

crwdns2935229:03crwdne2935229:0