crwdns2915892:0crwdne2915892:0

In this guide we show you how to a resolve jammed hotend/nozzles on open source "VORON2.4" style 3D printers.

With the growing popularity of open source style kit printers this guide hopes to help newer members of the community with a common issue that may arise on these types of printers.

This repair will help with alleviating minor clogs in the hotend. These clogs can be the culprit for sudden inconsistent extrusion. No hand tools are necessary.

-

-

Load the last filament used before the jam into the printer at normal printing temperature.

-

PLA: 180-210C

-

PETG: 230-250C

-

ABS: 240-255C

-

-

-

Extrude 5-10 mm at printing temp of plastic and then set hotend temp to 0/room temp.

-

Wait for hot end temp to drop to room temp.

-

-

-

-

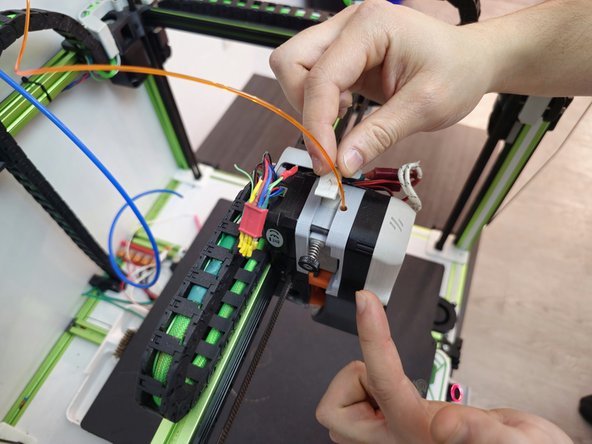

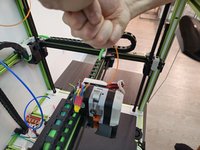

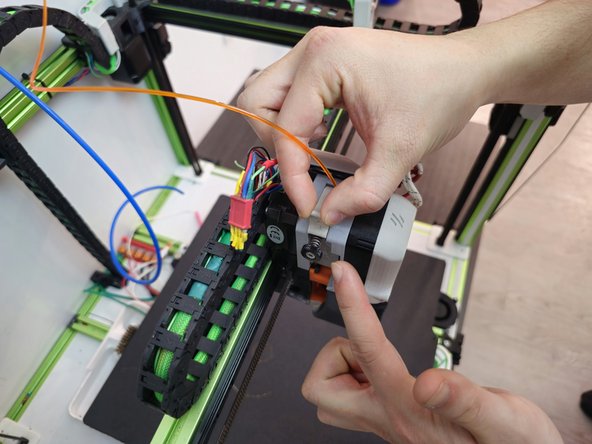

Remove all tension on extruder arm (the part that clamps to the filament to feed into printer).

-

-

-

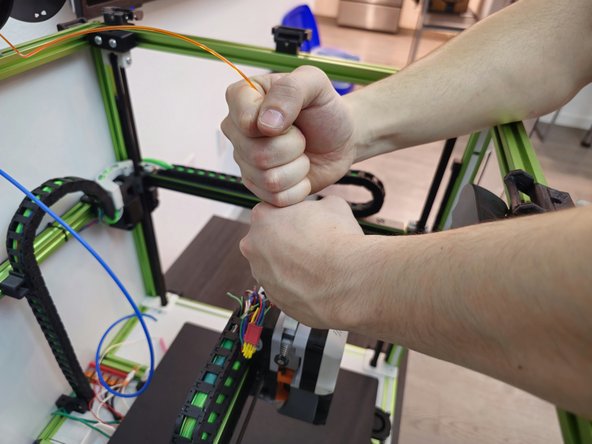

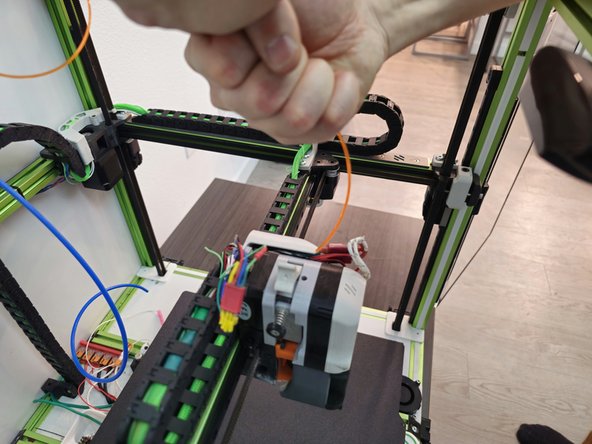

Pull te filament out of the hotend.

-

Repeat the previous steps one to two times.

-

-

-

Retension the extruder arm and set the hotend to the printing temp of material.

-

Extrude the material and note the behavior of the plastic as it exits the hotend.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.