crwdns2915892:0crwdne2915892:0

If your Dymo LabelManager 160 is not properly printing from Dymo D1 Label Cassettes, the wheelhead which unspools the cassettes may be not functioning. This guide leads you through the process of opening up the LabelManager and changing the wheelhead. Keep in mind that the device has loose parts.

Before you begin, make sure that your device is turned off and the battery is removed.

crwdns2942213:0crwdne2942213:0

-

-

Place the device face-down to access the battery compartment.

-

-

-

Remove the compartment cover to reveal the batteries. Remove the 6 old batteries.

-

-

-

To open the cartridge compartment, simply lift on the front of the device.

-

-

-

Using a Phillips #0 screwdriver, remove the four 1.3mm screws from the cartridge compartment and two 1.2mm screws from the battery compartment.

-

-

-

-

Using a spudger or other tool, lift and remove the front of the device. This should be done all around the device to ensure the two parts split correctly.

-

-

-

Gently remove the rubber keyboard from the device.

-

-

-

Using a Phillips #0 screwdriver, remove the three 1.1 mm screws from the circuit board.

-

-

-

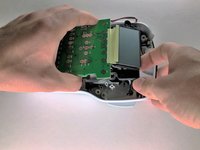

Lifting the circuit board, use a Phillips #1 screwdriver to remove the two 1.2mm screws from under the circuit board.

-

-

-

Proceed to lift the excess device components until the rollerblade is visible.

-

-

-

With the device components exposed, gently lift the wheelhead out of the label maker.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

crwdns2935221:0crwdne2935221:0

crwdns2935229:02crwdne2935229:0

crwdns2947412:04crwdne2947412:0

Group 9: Over all looks great. Pictures are great quality and hand placement in pictures. The circles and arrows should all be red. The only time the color changes is if there are different steps within a single picture.

thank you for the procedure, i mis one screen in the procedure how to detach display?

Guide does not properly address or account for parts that will simply fall out if you proceed with this course. Gears, springs, plastic bits, metal rods. I had a pile of seven or eight unknown bits, plus the plastic gears.

No photos of the gearing, or the levers that hold tension on the label ribbon. These are the parts will fall out.

All I’ve managed to do is take apart and reassemble, only to have pieces that are now out, who knows where they go. Device now gives me a label jam error when reassembled. Have no clue how the tensioner should be oriented.

Gonna move on and buy a new label maker now. Thanks for the frustration ifixit.

Same sad story ! I am not able to reassemble the device...