crwdns2915892:0crwdne2915892:0

If your Durofix RV332 cordless driver has stopped turning or is struggling to deliver the torque it used to, it’s quite likely that the internal motor assembly has worn out or failed altogether. This repair guide will take you step‑by‑step through removing the old motor and installing a matching replacement, restoring your tool’s full functionality. Before you dive in, you’ll want to ensure you have a clean, well‑lit workspace and a few basic tools: a Phillips #0 screwdriver to remove six screws on the housing, a plastic opening tool or spudger to gently separate the two halves of the casing, wire cutters or strippers to prepare the motor leads, and a soldering iron (or an alternative method of reconnecting the wires) to attach the leads securely to the new motor. Because you’ll be working inside a live cordless tool, it’s essential to remove the battery or isolate power first (to prevent accidental activation), and to take care when handling internal wiring and printed circuit board (PCB) components to avoid short‑circuits or damage. While the job is fairly straightforward for someone comfortable opening tools and soldering wire leads, you should take your time and proceed methodically: work slowly when prying the casing to avoid breaking plastic clips, keep track of all screws and parts, ensure the new motor’s terminals are clean and properly marked (positive/negative), and let the solder connections cool fully before reassembling. Once reinstalled, you’ll be able to re‑insert the battery, test the driver, and assuming everything’s gone according to plan, your RV332 will be back to delivering the rotation force it had when new. With patience and attention to detail, this motor swap is a practical way to revive a cordless driver rather than replace the entire unit.

Part# 3805-30529

crwdns2942213:0crwdne2942213:0

-

-

Use the Phillips #0 screwdriver to remove six 13 mm screws from the casing.

-

-

-

Use a plastic separating tool (or a prying tool) to gently pry apart the top and bottom halves of the driver’s plastic housing.

-

Work slowly around the edges to avoid cracking the plastic or damaging internal clips.

-

-

-

Once the casing is open, lift out the printed circuit board (PCB), battery, LED, and existing motor assembly as one unit from inside the housing.

-

Using wire cutters, cut the black and red motor wires where they connect to the motor. (You’ll later re-solder to the new motor.)

-

-

-

Strip about ¼ inch (≈ 6 mm) of insulation off the ends of both red and black wires.

-

Make sure the exposed wire is clean (unoxidized) and ready to solder.

-

-

-

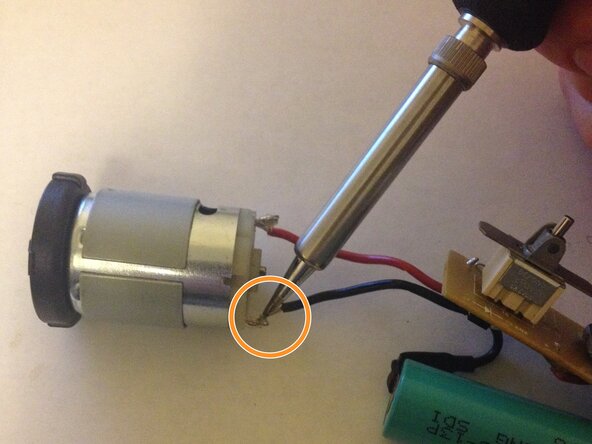

Solder the red wire to the motor’s positive terminal (usually marked with a “+” or a red circle).

-

Solder the black wire to the motor’s negative terminal (or the remaining terminal).

-

-

-

Place the motor, along with the PCB, LED, and battery, back into the plastic housing in the correct orientation.

-

Close the casing halves together, ensuring clips and alignment are correct.

-

Reinsert and tighten the six screws you removed earlier.

-

Finally, test the device to confirm the motor now works.

-

If everything functions, you're done. If not, reopen and re-check your soldering and connections.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.

crwdns2947410:01crwdne2947410:0

Too late finding this (although self-explanatory). I was wondering when I tried this - WHERE does one find the spare component motor to replace? I searched the internet, but for something so specific, I just couldn't locate the right channels. For future reference, is there a typical store of small motors, etc... to locate these things?