crwdns2915892:0crwdne2915892:0

This guide will show how to replace a faulty armature in the Dremel MultiPro 395.

crwdns2942213:0crwdne2942213:0

-

crwdns2935267:0crwdne2935267:0Flathead 3/32" or 2.5 mm Screwdriver$5.49

-

Remove the blue caps located on either side of the MultiPro, using a 3 mm flathead screwdriver.

-

-

-

Carefully remove the carbon brushes attached at the end of the springs by gently pulling on the springs using your hands.

-

-

-

Pull one side of the hanger up and then pull away from the Multipro until the other side can be pulled out.

-

-

-

Remove the 4 screws located on the bottom of the Multipro with a T15 screwdriver.

-

-

-

-

Hold down the collet lock, remove the chuck cap from the top of the Multipro by screwing counterclockwise.

-

-

-

Remove the black housing cap from the Multipro located directly below the chuck cap.

-

-

-

Pull the bottom side of the casing up to remove it.

-

-

-

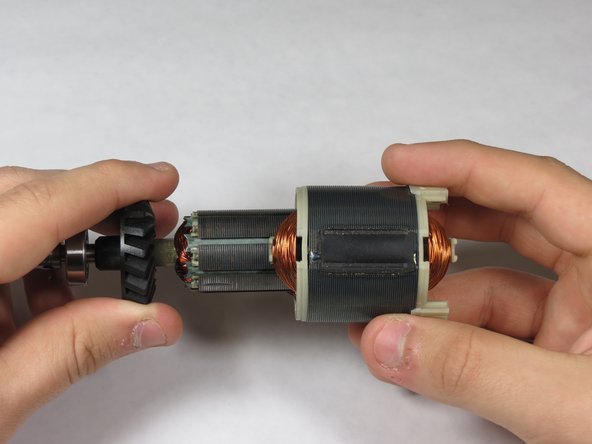

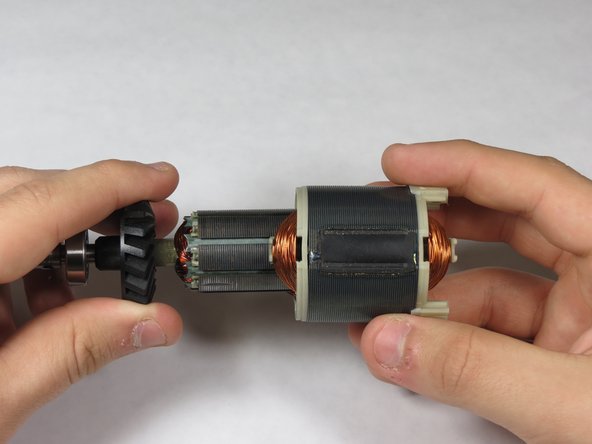

Gently lift the motor shaft out of the Multipro.

-

-

-

Remove the rubber ring from the bottom of the armature.

-

-

-

Pull the on/off switch off of the 120V field, paying careful attention to the prongs on the on/off switch.

-

For reassembly, make sure the prongs are touching the metal connectors on the bottom of the 120V field

-

-

-

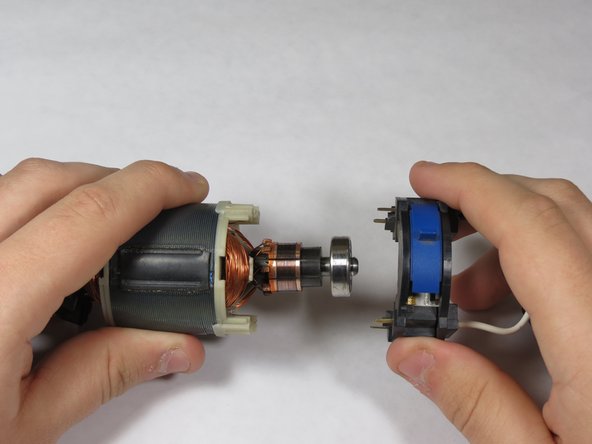

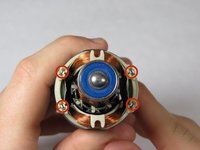

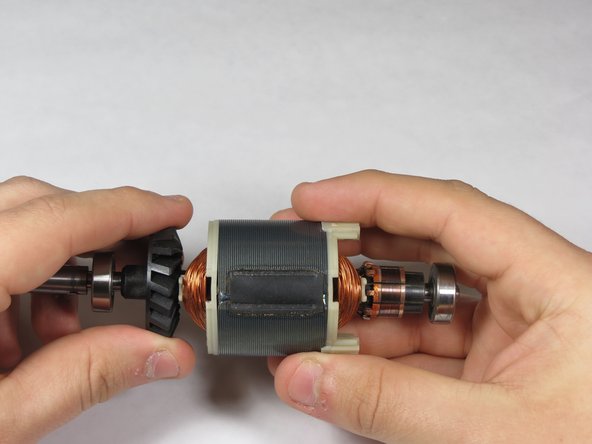

Carefully slide the armature out of the 120V field.

-

-

-

Carefully slide the new armature back into the 120V field.

-

To reassemble your device, follow these instructions in reverse order.

crwdns2935221:0crwdne2935221:0

crwdns2935229:06crwdne2935229:0

crwdns2947412:07crwdne2947412:0

This part does not seem to be my problem the only thing I have left on the shaft is the copper coil the fan and whatever the part above the fan it spins freely around and it seems to be set on a device that allows it to tilt. I am struggling with this, please point me in the right direction of the removal of the copper core coil.... There has got to be an easier way to remove this.

You dont remove the armature coil, you replace the entire rotating armature assembly...why are you trying to take the coil off?!?

The article does not mention why an armature needs to be replaced. So why is it necessary to replace an armature? If there is no obviously visible problem, what could be wrong with it?

Failed front bearing. I have a 398 and the front bearing gets bathed in whatever youre cutting ... Like drywall dust, plaster, stone dust. And you cant just pull the collet mount off and replace the bearing, so you have to replace the whole armature (great design, dremel!). The good news is youll have fresh bearings and commutator (which should help the brush whine some). Youll also have a spare armature to carefully cut the collet shaft off of (hopefully in a way you can remount it...remember to rebalance the armature afterwards), then use a gear puller to take the front bearing off, and replace it with a better, more shielded one. Then youll have a replacement armature for when the first replacement front bearing jams up!

There could also be a broken fan, bent shaft, an electrical issue inside the windings...lots of reasons to need to replace the armature. Its just stupid you cant take the freaking front bearing off and have to replace the whole %#*@ assembly....

very good article, congratulations for the content

<a href="https://comodemorarpragozar.com/"> comodemorarpragozar </a>