crwdns2915892:0crwdne2915892:0

In these instructions, I will show you how to carry out a typical wear repair on these plastic parts in just a few steps. I call the repaired part the Blinds lock, the official Dometic designation is "lock for central one-hand operation".

The fault situation is that one or both sides of the blinds no longer engage in the guide rails and the blinds are therefore not held in position, which usually also causes consequential damage.

These instructions show you how to repair the problem without spare parts.

If you prefer to replace the parts, you can try the following set:

BG1089 Dometic Seitz parts set S3_S4 window, gray parts set no. 37

Included are:

1 set of guide piece for blackout blind (VD)

1 set of guide piece for flyscreen roller blind (FS)

1 side counter bracket on sun protection (for window width greater than 900 mm)

1 pc. Side counter-holder on flyscreen (for window width greater than 900 mm)

1 lock for central one-hand operation

1 meter dovetail profile

1 pair of sliders

I have already carried out this repair myself on several roller blinds. Since then I have had no more problems and the repair has lasted many tens of thousands of kilometers.

crwdns2942213:0crwdne2942213:0

-

-

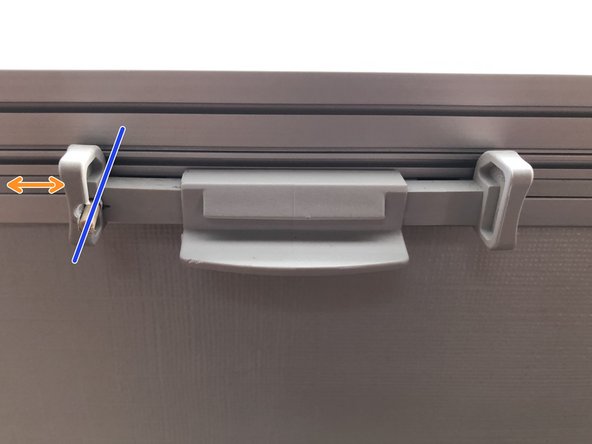

This step shows the problem again for analysis and confirmation.

-

When the lock is pressed...

-

the slider no longer moves or...

-

the hole is visible after pressing

-

-

-

This explanation is intended to help you understand the following steps

-

To solve the problem...

-

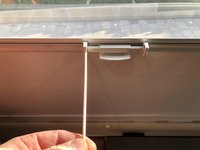

a wooden stick (shashlik skewer) is passed through a hole in the catch...

-

which ends in the hole behind it and...

-

thereby taking the slider with it again...

-

and restores the function in the long term

-

-

-

Pull the blinds to a half-height position

-

Manually engage the catches in the guide rails

-

-

-

Press the catch together until the hole is visible

-

Measure the diameter of the hole with the correct side of the calliper gauge

-

In my case it measured 3 mm

-

-

-

-

Mark the center of the drill hole with a pencil

-

Make sure that the hole in the sliding strip is aligned with the markings

-

Later on the shashlik skewer has to be inserted straight and directly into the hole

-

-

-

To increase precision, I recommend pre-drilling the hole with a 1 mm drill bit or...

-

to center punch the holes before drilling

-

-

-

To protect the sliding ledge, a protection should be placed between the locking mechanism and the sliding ledge, in my case a metal strip

-

This is to prevent drilling too far and damaging the sliding strip

-

I fixed this with masking tape

-

-

-

with the 3 mm drill bit...

-

horizontally and diagonally straight (i.e. better than shown in the pictures)...

-

drill through the two markings.

-

Make sure you stop before you get into the material behind!

-

-

-

Again, make sure that it is held against the blinds from behind

-

Insert the shashlik skewer with the flat end into the drilled hole and thread it into the existing hole in the slider

-

Take care not to insert the skewer too far, as this will cause a blockage

-

Test whether the function is restored

-

-

-

Use the Japanese saw / fine saw to saw the shashlik skewer...

-

saw off flush

-

-

-

Finally, check the complete function again

-

So, now you're done and hopefully you'll enjoy your functioning roller blinds for years to come.

So, now you're done and hopefully you'll enjoy your functioning roller blinds for years to come.

crwdns2934873:0crwdne2934873:0

100%

crwdns2934883:0oldturkey03crwdne2934883:0 crwdns2934875:0crwdne2934875:0

crwdns2934877:0crwdne2934877:0 ›